In many industries, precision is key to maintaining product quality, ensuring safety, and optimizing resources. One tool that plays a crucial role in achieving these standards is the thickness gauge meter. By providing accurate measurements of material thickness, thickness gauge meters are indispensable in fields like manufacturing, automotive, aerospace, and construction. However, understanding and interpreting these readings correctly is vital for anyone who uses this tool. This guide will walk you through the basics of thickness gauge meter readings, factors affecting accuracy, and tips for ensuring reliable results.

What is a Thickness Gauge Meter?

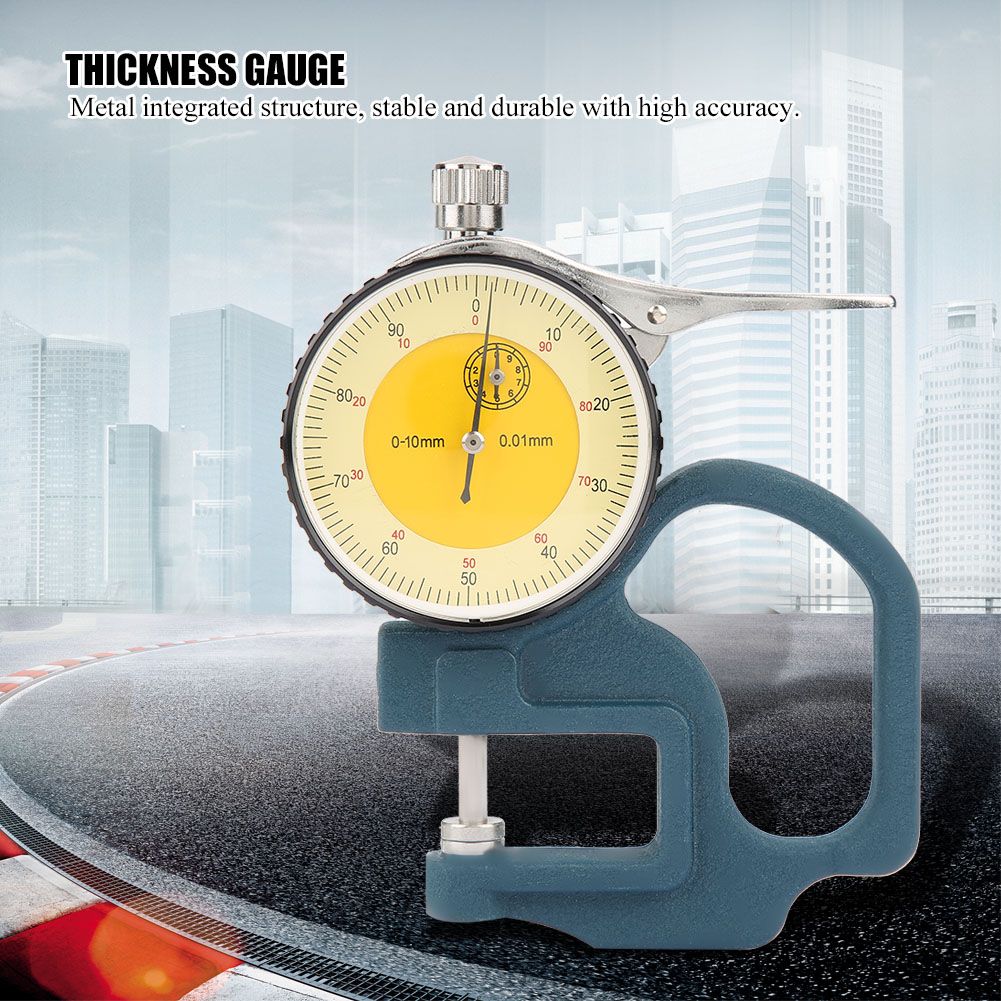

A thickness gauge meter is a device used to measure the thickness of materials like metal, plastic, glass, rubber, and even coatings. It’s commonly used in quality control processes, ensuring products meet specific thickness requirements. Thickness gauge meters can be categorized into two main types: contact-based and non-contact-based. Contact-based thickness gauge meters require physical touch with the material, whereas non-contact versions (like ultrasonic gauges) use sound waves to measure thickness without direct contact.

Each type has its unique applications. For instance, ultrasonic thickness gauge meters are often used to measure the thickness of pipes, tanks, and metal structures, as they can work even if the surface is coated or corroded. Understanding which type suits your needs is the first step to accurate measurements.

Reading a Thickness Gauge Meter

When using a thickness gauge meter, it’s essential to follow proper procedures to ensure accuracy. Here’s a general outline of how to take measurements with a thickness gauge meter:

- Calibrate the Meter: Calibration is critical. Most thickness gauge meters come with standard blocks or calibration tools to set a baseline before measurements. Accurate calibration will ensure that the readings reflect the true thickness of the material.

- Check the Material Type and Conditions: Different materials can yield different readings due to density and other physical properties. Adjust the gauge settings according to the specific material you’re measuring.

- Place the Meter Properly: Ensure that the meter’s probe is perpendicular to the surface. Any tilt can affect the reading and lead to inaccuracies.

- Take Multiple Measurements: Variations can occur due to inconsistencies in the material or surface conditions. Take readings at multiple points to get an average thickness, especially for larger surfaces.

- Interpret the Readings: After recording the readings, you’ll want to compare them to the specifications for the material or project requirements. This comparison helps determine if the material meets quality standards.

Factors Affecting Thickness Gauge Meter Readings

Several factors can impact the accuracy of a thickness gauge meter. Recognizing these variables can help you troubleshoot unexpected readings and make necessary adjustments for reliable results.

- Material Properties: Different materials have unique properties that affect how sound waves or probes interact with them. Materials like metals, rubber, and glass can yield different readings due to their density and structure.

- Temperature: High temperatures can alter the properties of certain materials, which can, in turn, affect the accuracy of the readings. Some thickness gauge meters are designed for high-temperature applications, but it’s essential to verify that your device is suitable for the working conditions.

- Surface Coatings: For non-contact gauge meters like ultrasonic meters, coatings or paint on the surface can interfere with sound waves, affecting the reading. Some advanced models can compensate for coatings, but it’s always important to account for this factor.

- Calibration: Calibration errors are one of the most common causes of inaccurate readings. Make sure to recalibrate the meter regularly, especially if it’s used on different materials or in varying environmental conditions.

- Surface Roughness: A smooth surface will generally yield more accurate readings. Rough surfaces can create gaps between the probe and the material, leading to unreliable measurements. In such cases, using a coupling gel for ultrasonic gauges can improve contact and accuracy.

Tips for Getting Accurate Results

Achieving accurate and consistent results with a thickness gauge meter requires attention to detail. Here are some tips to help you maximize the effectiveness of this tool:

- Follow a Regular Calibration Schedule: Regular calibration ensures that your thickness gauge meter is accurate and reliable. Keep a log of calibration checks, as this can also help in tracing back any measurement discrepancies.

- Train Your Team Properly: Proper training in handling and using the thickness gauge meter is essential. Make sure all users understand the importance of calibration, probe placement, and how to interpret readings accurately.

- Understand Limitations: Each thickness gauge meter has its limitations based on type, range, and design. Know what your device can and cannot measure to avoid erroneous readings.

- Use High-Quality Couplant: If you’re using an ultrasonic thickness gauge meter, apply a high-quality couplant (gel) between the probe and the surface. This will eliminate air gaps and help get consistent measurements on rough surfaces.

- Store the Meter Carefully: When not in use, store the thickness gauge meter in a safe, dry place to protect it from environmental factors that may impact its accuracy or longevity.

Conclusion

A thickness gauge meter is a powerful tool that ensures product quality and consistency by providing precise material thickness measurements. To make the most of it, users need to understand how to read the device correctly, recognize factors affecting its accuracy, and follow best practices for consistent results. By mastering these aspects, you can confidently use a thickness gauge meter in quality control, helping to maintain high standards and improve overall productivity in any industry.

I really like your website it is amazing