When embarking on a design that requires the use of galvanized welded mesh, opting for the right type is pivotal for icing continuity, functionality, and cost- effectiveness. Whether you are working on construction, husbandry, or a DIY home design, understanding the specific requirements of your task will help you choose the stylish mesh. In this blog, we will guide you through the crucial factors to consider when opting for galvanized welded mesh, icing you make an informed decision.

Understanding Galvanized Welded Mesh

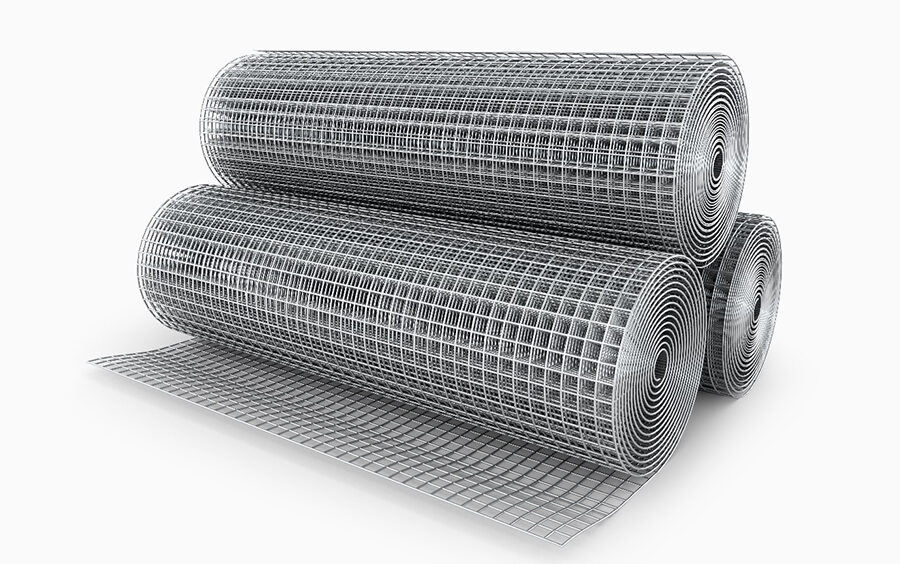

Galvanized welded mesh is a protean and durable material made by welding sword cables at their corners and also sheeting them with a subcaste of zinc. This process provides excellent erosion resistance, making it ideal for out-of-door and artificial operations. The mesh comes in colorful sizes, needles, and coatings, each suited for different purposes.

Crucial Factors to Consider:

1. Mesh Size and line Gauge

The mesh size and line hand are abecedarian aspects to consider. snare size refers to the distance between the cables, while the line hand indicates the consistency of the cables. Then’s how to choose grounded on your requirements

Construction systems: For buttressing concrete or other construction tasks, lower mesh size and thicker line hand give the necessary strength and stability.

Agriculture: For fencing and beast enclosures, a medium mesh size with a moderate line hand is generally sufficient. It provides a balance between strength and inflexibility.

DIY systems: For home systems similar as theater fencing or scenery, choose a mesh size and line hand that is aesthetically pleasing yet functional.

2. Coating Consistence

The consistence of the galvanized coating significantly impacts the mesh’s continuity and erosion resistance. Thicker coatings give better protection, especially in harsh surroundings. Then’s a guideline

Outdoor Use Opt for a mesh with a thicker galvanized coating to repel rainfall rudiments.

Inner Use A standard coating consistence is generally sufficient for inner systems where exposure to humidity and sharp rudiments is limited.

3. operation-Specific Conditions

Consider the specific conditions of your design. Different operations may demand specific parcels from the mesh

Security Fencing For high-security areas, a thicker line hand and lower mesh size enhance strength and deterrence.

Beast Closes ensures the mesh size is applicable to help escape while allowing visibility and ventilation.

underpinning In construction, the mesh should misbehave with applicable structure canons and norms for structural integrity.

Choosing a Reliable Supplier

Opting a estimable supplier is as important as choosing the right type of mesh. Look for suppliers with a proven track record of furnishing high- quality products. However, you might consider searching for a welded wire mesh supplier in UAE to ensure original vacuity and compliance with indigenous norms, If you are in the UAE.

Installation Considerations

Proper installation is crucial to maximizing the performance and lifetime of your galvanized welded mesh. There are many tips:

Ensure establishment Fixing: Secure the mesh forcefully to its frame to help sagging or relegation.

Avoid Cutting: When cutting the mesh to fit, be aware not to damage the galvanized coating, as this can lead to rusting.

Use Appropriate Fasteners: Choose fasteners that are compatible with galvanized accouterments to avoid galvanic erosion.

Conservation Tips

Indeed though the galvanized welded mesh is low conservation, regular checks and simple keep can extend its life

Regular examinations: Periodically check for any signs of damage or erosion, especially in high- stress areas.

Drawing Clean: the mesh periodically to remove dirt and debris that can beget wear and tear over time.

Defensive Coatings; Consider applying fresh defensive coatings in extremely sharp surroundings to enhance continuity.

Conclusion

Choosing the right galvanized welded mesh for your design involves careful consideration of mesh size, line hand, coating consistence, and specific operation conditions. By understanding these factors and opting a dependable supplier, you can ensure that your mesh will meet the demands of your design and stand the test of time. Whether for construction, husbandry, or DIY systems, the right mesh will give the strength, continuity, and functionality you need.

Flash back, a well-informed choice moment can save you time, plutocrats, and trouble in the future, icing your design’s success and life.