In today’s globalized manufacturing landscape, China has emerged as a powerhouse for injection molding solutions. Whether you’re in the market for precision medical device molds or durable appliance plastic components, understanding how to navigate the Chinese market is crucial. This guide will walk you through the process of sourcing top-notch medical injection molding and consumer appliance plastic molds from China, ensuring you make informed decisions and forge successful partnerships.

Why Choose China for Injection Molding?

Before diving into the sourcing process, let’s explore why China has become a go-to destination for injection molding:

- Cost-effectiveness

- Advanced manufacturing capabilities

- Vast supplier network

- Rapid prototyping and production

- Flexible customization options

Understanding Medical Injection Molding Requirements

When it comes to medical injection molding, precision and quality are paramount. Here’s what you need to consider:

- Material selection

- Cleanroom manufacturing

- Regulatory compliance (FDA, ISO 13485)

- Biocompatibility testing

- Sterilization capabilities

- Traceability and documentation

Consumer Appliance Plastic Mold Considerations

For consumer appliance molds, durability and aesthetics often take center stage. Key factors include:

- Heat resistance

- Impact strength

- Color consistency

- Surface finish options

- Assembly requirements

- Cost-effective production at scale

Identifying Reputable Chinese Suppliers

Finding the right supplier is crucial for success. Here are some strategies to help you identify trustworthy partners:

- Attend trade shows and industry events

- Utilize online B2B platforms

- Seek recommendations from industry peers

- Research company history and certifications

- Request sample products and prototypes

Evaluating Supplier Capabilities

Once you’ve shortlisted potential suppliers, it’s time to assess their capabilities:

- Production capacity

- Quality control measures

- Design and engineering expertise

- Communication and responsiveness

- Financial stability

- References from past clients

Negotiating Terms and Pricing

Effective negotiation is key to securing favorable terms. Consider these factors:

- Volume-based pricing

- Payment terms and methods

- Intellectual property protection

- Warranty and liability agreements

- Shipping and logistics arrangements

Quality Assurance for Medical Injection Molding

Ensuring consistent quality in medical injection molding is critical. Implement these measures:

- Regular audits and inspections

- In-process quality checks

- Material certifications

- Dimensional accuracy testing

- Functional testing protocols

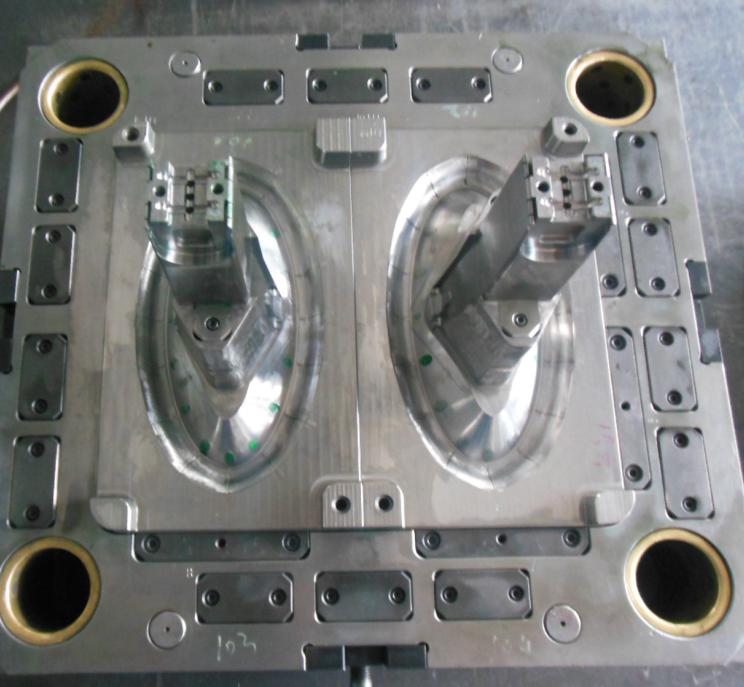

Optimizing Consumer Appliance Plastic Mold Production

To maximize efficiency in consumer appliance mold production, focus on:

- Design for manufacturability (DFM)

- Mold flow analysis

- Cycle time optimization

- Automated part removal

- Secondary operations integration

Managing Communication and Cultural Differences

Effective cross-cultural communication is essential for successful partnerships. Tips include:

- Learn basic Mandarin phrases

- Understand Chinese business etiquette

- Use clear and concise language

- Employ professional translators when needed

- Be patient and flexible in negotiations

Navigating Regulatory Compliance

Compliance with international standards is crucial, especially for medical devices. Key considerations:

- FDA regulations

- CE marking requirements

- ISO 13485 certification

- Material safety data sheets (MSDS)

- RoHS and REACH compliance

Implementing Quality Control Measures

Robust quality control processes ensure consistent product quality:

- Incoming material inspection

- In-process quality checks

- Final product testing

- Statistical process control (SPC)

- Non-conformance reporting and corrective actions

Logistics and Shipping Considerations

Efficient logistics management is crucial for timely delivery:

- Choose appropriate shipping methods

- Understand Incoterms and customs procedures

- Properly package and label products

- Consider using a freight forwarder

- Plan for potential delays and contingencies

Building Long-Term Partnerships

Fostering strong relationships with Chinese suppliers can lead to long-term success:

- Regular communication and feedback

- Joint continuous improvement initiatives

- Mutual goal-setting and performance reviews

- Cultural exchange and relationship-building activities

- Collaborative problem-solving approach

Technology Integration in Injection Molding

Staying ahead of technological advancements is crucial in the injection molding industry:

- Industry 4.0 and smart manufacturing

- 3D printing for rapid prototyping

- Advanced simulation software

- Robotic automation in production

- Internet of Things (IoT) for real-time monitoring

Sustainability in Injection Molding

Embracing sustainable practices is increasingly important:

- Use of recycled and bio-based materials

- Energy-efficient machinery

- Waste reduction strategies

- Closed-loop recycling systems

- Carbon footprint reduction initiatives

Case Studies: Success Stories in Chinese Injection Molding

Let’s examine some real-world examples of successful partnerships:

Case Study 1: Medical Device Manufacturer A US-based medical device company partnered with a Chinese supplier for injection molding of complex components. Through rigorous quality control and clear communication, they achieved a 30% cost reduction while maintaining FDA compliance.

Case Study 2: Home Appliance Brand A European appliance manufacturer sourced plastic molds from China, resulting in a 40% increase in production efficiency and significant cost savings. Key to their success was a collaborative approach to design optimization.

Comparison: Medical vs. Consumer Appliance Molds

AspectMedical Injection MoldingConsumer Appliance Plastic Molds

| Precision | Ultra-high | Moderate to high |

| Regulatory Requirements | Stringent (FDA, ISO 13485) | Standard consumer safety |

| Material Selection | Biocompatible, medical-grade | Durable, cost-effective |

| Production Environment | Cleanroom | Standard factory |

| Quality Control | Extensive documentation | Regular QC processes |

| Cost | Higher due to regulations | More competitive |

| Typical Volumes | Lower, specialized | Higher volume production |

Future Trends in Chinese Injection Molding

As we look ahead, several trends are shaping the future of injection molding in China:

- Increased automation and robotics integration

- Advanced materials development

- Shift towards high-value, complex parts

- Greater focus on sustainability

- Enhanced digital connectivity and traceability

Conclusion: Mastering the Art of Sourcing from China

Sourcing medical injection molding and consumer appliance plastic molds from China offers tremendous opportunities for businesses worldwide. By understanding the unique requirements of each industry, building strong partnerships, and implementing robust quality control measures, you can leverage China’s manufacturing expertise to your advantage. Remember, success lies in thorough research, clear communication, and a commitment to continuous improvement.