A Guide to the Versatility and Worth of Elastic Tapes

In today’s diverse manufacturing and crafting industries, the role of tape elastic and tape nylon is crucial. These versatile materials, often grouped under the broader category of elastic tapes, are indispensable for a range of applications, from apparel design to industrial uses. This article explores the significance of these materials and the impact of elastic manufacturers in providing high-quality solutions.

Understanding Tape Elastic and Tape Nylon

Tape elastic, as the name suggests, is a type of flexible, stretchable tape used in various applications where elasticity is required. It is commonly employed in clothing, especially in waistbands, cuffs, and as a means of adding flexibility and comfort to garments. Tape elastic is designed to stretch and return to its original shape, offering both durability and adaptability.

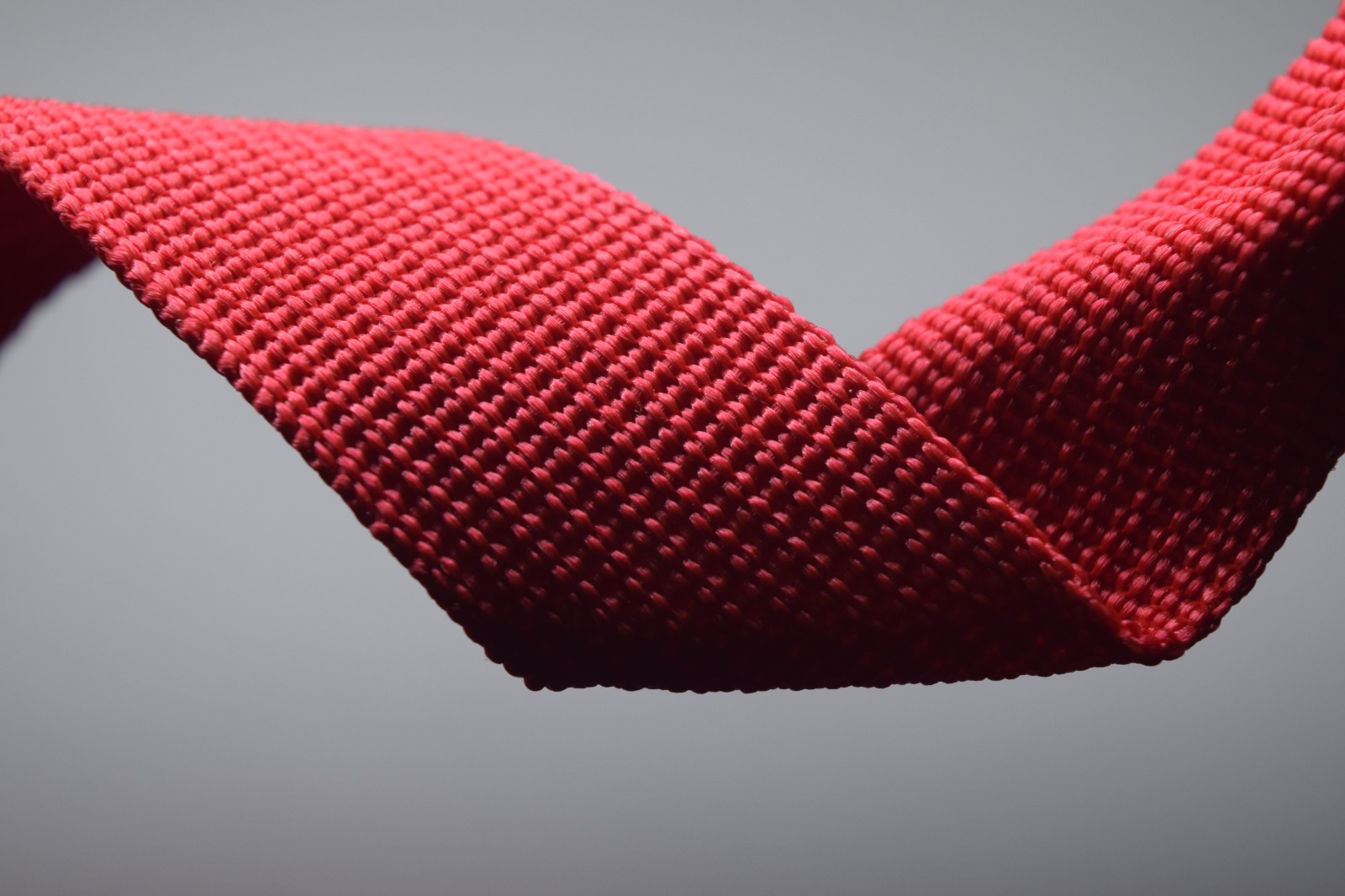

On the other hand, tape nylon is made from nylon fibers, which are known for their strength and resilience. Nylon tapes are often used in more demanding applications where strength and durability are paramount. They are resistant to abrasion, chemicals, and environmental conditions, making them suitable for use in both industrial and consumer products.

Applications of Elastic Tapes

Elastic tapes have a broad range of applications. In the fashion industry, they are used in the construction of garments to provide a snug fit while allowing for flexibility. For instance, they are used in sportswear to enhance performance by providing unrestricted movement. In medical settings, elastic tapes are utilized in bandages and supports to offer compression and aid in recovery.

In the industrial sector, elastic tapes are employed in packaging and assembly processes. Their stretchability allows them to secure items tightly while accommodating changes in size and shape. This adaptability is especially useful in automated processes where precise handling is essential.

The Role of Elastic Manufacturers

Elastic manufacturers play a critical role in the production of both tape elastic and tape nylon. These manufacturers ensure that the tapes meet specific standards and specifications required for different applications. They invest in advanced technologies and materials to produce tapes that offer optimal performance.

Manufacturers focus on several key aspects when producing elastic tapes. Firstly, the elasticity of the tape must be consistent to ensure reliable performance. For tape nylon, the emphasis is on achieving the right balance between strength and flexibility. Additionally, manufacturers often offer custom solutions to meet unique requirements, such as specific widths, colors, and textures.

Choosing the Right Elastic Tape

When selecting elastic tapes for a particular application, several factors need to be considered. For apparel and soft goods, tape elastic is usually preferred due to its comfort and stretchability. For more rugged uses, such as industrial applications, tape nylon may be the better choice due to its superior strength and durability.

It’s also important to consider the manufacturing quality of the tape. Reliable manufacturers will provide detailed product information and testing results to ensure that the tapes meet industry standards. Working with reputable elastic manufacturers can help in obtaining products that are not only high in quality but also cost-effective.

Conclusion

Elastic tapes, including tape elastic and tape nylon, offer significant benefits across various industries. Their versatility and functionality make them indispensable in both everyday products and specialized applications. By understanding the distinct properties of these tapes and selecting products from reputable elastic manufacturers, businesses and consumers can ensure they achieve the best performance and value. Whether you’re designing a new garment or optimizing an industrial process, the right elastic tape can make all the difference.