Alumina ceramics, also known as aluminum oxide (Al2O3) ceramics, are one of the most widely used and versatile ceramic materials in engineering and technology. With their exceptional mechanical properties, thermal stability, and chemical resistance, alumina ceramics are pivotal in numerous high-performance applications across various industries. This comprehensive article explores the unique characteristics, manufacturing processes, and diverse applications of alumina ceramics, highlighting their crucial role in modern engineering.

Unique Properties of Alumina Ceramics

Alumina ceramics are characterized by a range of distinctive properties that make them highly valuable in various applications:

- High Hardness and Wear Resistance: Alumina is one of the hardest materials known, with a hardness rating of around 9 on the Mohs scale. This makes alumina ceramics highly resistant to wear and abrasion, ideal for applications requiring long-lasting durability.

- Excellent Thermal Stability: Alumina ceramics can withstand high temperatures, often exceeding 1500°C, without significant degradation. This property makes them suitable for use in high-temperature environments.

- Superior Chemical Resistance: Alumina is chemically inert and resistant to corrosion from most chemicals, acids, and alkalis. This makes alumina ceramics ideal for use in harsh chemical environments.

- Electrical Insulation: Alumina ceramics are excellent electrical insulators, with high resistivity even at elevated temperatures. This property is crucial for applications in the electronics and electrical industries.

- Low Thermal Expansion: The low thermal expansion coefficient of alumina ceramics ensures dimensional stability and resistance to thermal shock, making them suitable for applications involving rapid temperature changes.

- High Compressive Strength: Alumina ceramics possess high compressive strength, enabling them to withstand heavy loads and pressures without deforming or failing.

Manufacturing Processes of Alumina Ceramics

The production of alumina ceramics involves several critical steps to ensure the material achieves its desired properties:

Raw Material Preparation

The primary raw material for alumina ceramics is aluminum oxide powder, which is derived from bauxite ore through the Bayer process. The high-purity alumina powder is then processed to achieve the desired particle size and purity.

Powder Processing

The alumina powder is thoroughly mixed with binders, plasticizers, and other additives to create a homogeneous mixture. This step is crucial for ensuring uniformity and consistency in the final product.

Shaping

The processed powder is shaped into the desired forms using various techniques, including:

- Pressing: This method involves compacting the powder in a die under high pressure to form a green body with the desired shape. Both uniaxial and isostatic pressing techniques can be used, depending on the complexity of the shape.

- Extrusion: In extrusion, the powder mixture is forced through a die to create long shapes with uniform cross-sections, such as rods, tubes, and profiles.

- Injection Molding: This technique is used for producing complex shapes. The powder mixture is injected into a mold and solidified, allowing for the creation of intricate geometries.

- Slip Casting: In slip casting, a slurry of alumina powder and water is poured into a porous mold, allowing the water to be absorbed and the alumina particles to consolidate into the desired shape.

Drying and Pre-Sintering

The shaped green bodies are dried to remove any residual moisture and then pre-sintered (bisque fired) at a lower temperature to remove binders and organic additives. This step helps improve the mechanical strength of the green bodies before final sintering.

Sintering

The dried and pre-sintered bodies are sintered at high temperatures, typically between 1600°C and 1800°C, to achieve full densification. During sintering, the alumina particles bond together, resulting in a strong, dense ceramic material. The sintering atmosphere and temperature profile are carefully controlled to optimize the properties of the final product.

Finishing

After sintering, the alumina ceramics may undergo finishing processes such as grinding, lapping, and polishing to achieve the desired dimensions and surface finish. Advanced machining techniques, including diamond grinding, are often used due to the material’s extreme hardness.

Applications of Alumina Ceramics

Thanks to their exceptional properties, alumina ceramics find applications in a wide range of industries. Here are some of the most notable uses:

Electronics and Electrical Industry

Alumina ceramics are widely used in the electronics and electrical industries due to their excellent electrical insulation and thermal properties:

- Substrates: Alumina is used as a substrate material in electronic circuits, providing a stable and insulating base for components.

- Insulators: Alumina ceramics are used as insulators in high-voltage applications, ensuring safe and reliable operation of electrical systems.

- Semiconductor Components: The thermal stability and electrical insulation properties of alumina make it ideal for semiconductor components and packaging.

Mechanical and Wear Applications

The high hardness and wear resistance of alumina ceramics make them suitable for various mechanical and wear applications, including:

- Cutting Tools: Alumina ceramics are used in cutting tools for machining hard materials, offering superior wear resistance and tool life.

- Wear Parts: Components such as bearings, seals, and valves benefit from alumina’s wear resistance, ensuring long-lasting performance in demanding environments.

- Grinding Media: Alumina is used as grinding media in milling processes, providing efficient and durable performance.

Medical and Dental Applications

Alumina ceramics are biocompatible and inert, making them suitable for medical and dental applications:

- Implants: Alumina is used in orthopedic implants, such as hip and knee replacements, due to its biocompatibility, wear resistance, and mechanical strength.

- Dental Prosthetics: Alumina ceramics are used in dental crowns, bridges, and other prosthetics, offering aesthetics, durability, and biocompatibility.

Chemical and Environmental Applications

The chemical resistance and thermal stability of alumina ceramics make them ideal for use in chemical and environmental applications:

- Catalyst Supports: Alumina is used as a support material for catalysts in chemical reactions, providing a stable and inert platform.

- Filtration: Alumina ceramics are used in filtration systems for water and air purification, offering high durability and chemical resistance.

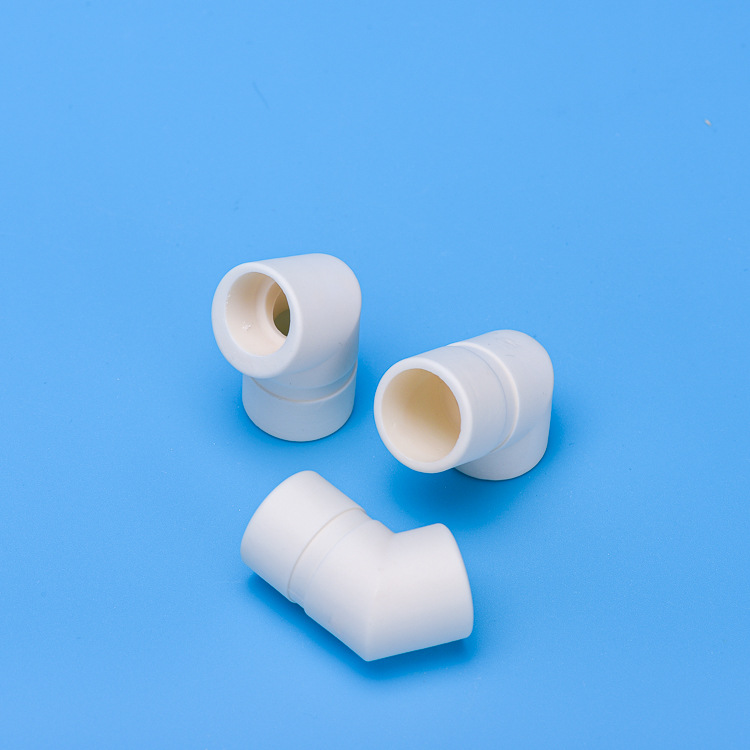

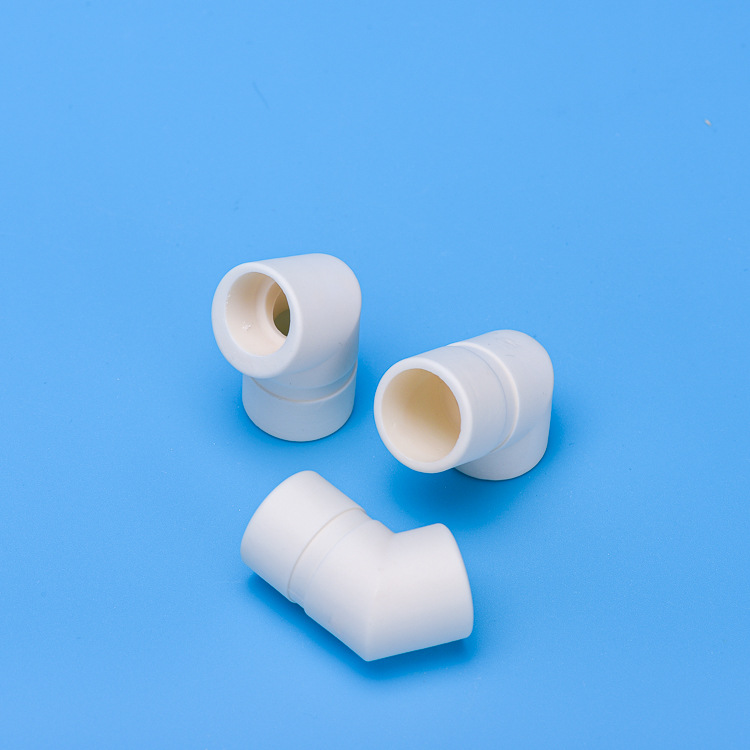

- Chemical Processing Equipment: Components such as pumps, pipes, and reactors benefit from alumina’s resistance to corrosion and high temperatures.

Energy Sector

Alumina ceramics play a crucial role in the energy sector, particularly in high-temperature and renewable energy applications:

- Insulating Components: Alumina is used in insulating components for gas turbines, ensuring efficient operation at high temperatures.

- Solar Panels: Alumina is used in the manufacturing of solar panels, providing stability and durability in harsh environmental conditions.

- Nuclear Applications: The material’s radiation resistance and thermal stability make it suitable for use in nuclear reactors and other radiation-intensive environments.

Future Trends and Developments

The future of alumina ceramics is promising, with ongoing research and development aimed at enhancing their properties and expanding their applications. Here are some exciting trends to watch:

Nanotechnology

Researchers are exploring the development of nanostructured alumina, which could offer even better mechanical properties and thermal stability. This could lead to more advanced applications across various industries, including electronics, medicine, and energy.

Additive Manufacturing

3D printing, also known as additive manufacturing, is revolutionizing the production of alumina ceramics. This technology allows for the creation of complex, high-precision components with less waste and shorter lead times. Additive manufacturing could enable the production of custom-designed alumina components for specialized applications.

Advanced Composites

Scientists are investigating the development of alumina composites that combine alumina with other materials to enhance their properties. These advanced composites could offer improved performance and new functionalities, further expanding the range of applications for alumina ceramics.

Environmental Sustainability

There is a growing focus on making alumina ceramics more environmentally friendly. Researchers are looking at ways to reduce the environmental impact of alumina production, such as using renewable energy sources and recycling materials. Sustainable alumina ceramics could help make manufacturing greener and reduce carbon footprints.

Conclusion

Alumina ceramics are a remarkable class of materials that combine exceptional mechanical properties, thermal stability, and chemical resistance. These unique characteristics make alumina ceramics an ideal choice for a wide range of high-performance applications across various industries. As research and technology continue to advance, alumina ceramics are poised to play an even greater role in shaping the future of advanced materials. Whether through the development of nanostructured materials, the adoption of additive manufacturing techniques, or the exploration of advanced composites, alumina ceramics will continue to push the boundaries of what is possible in materials science and engineering.

equilibrado dinámico

Aparatos de balanceo: fundamental para el operación estable y efectivo de las maquinarias.

En el campo de la innovación contemporánea, donde la eficiencia y la seguridad del dispositivo son de alta significancia, los sistemas de balanceo juegan un función esencial. Estos sistemas adaptados están diseñados para calibrar y regular partes móviles, ya sea en maquinaria de fábrica, medios de transporte de traslado o incluso en dispositivos caseros.

Para los profesionales en conservación de dispositivos y los especialistas, operar con sistemas de equilibrado es importante para proteger el funcionamiento fluido y confiable de cualquier mecanismo rotativo. Gracias a estas opciones modernas avanzadas, es posible limitar sustancialmente las vibraciones, el ruido y la carga sobre los cojinetes, prolongando la vida útil de piezas importantes.

Asimismo relevante es el papel que tienen los equipos de balanceo en la soporte al consumidor. El apoyo profesional y el conservación regular utilizando estos equipos posibilitan brindar soluciones de gran excelencia, aumentando la contento de los clientes.

Para los propietarios de negocios, la contribución en unidades de equilibrado y medidores puede ser esencial para mejorar la eficiencia y rendimiento de sus equipos. Esto es particularmente significativo para los dueños de negocios que dirigen pequeñas y intermedias empresas, donde cada punto importa.

Por otro lado, los dispositivos de ajuste tienen una vasta aplicación en el sector de la seguridad y el monitoreo de calidad. Facilitan localizar posibles fallos, evitando arreglos costosas y problemas a los aparatos. Incluso, los información extraídos de estos aparatos pueden aplicarse para mejorar sistemas y incrementar la exposición en buscadores de exploración.

Las áreas de uso de los aparatos de balanceo abarcan múltiples industrias, desde la fabricación de vehículos de dos ruedas hasta el supervisión ambiental. No influye si se habla de importantes elaboraciones manufactureras o modestos establecimientos domésticos, los aparatos de ajuste son necesarios para garantizar un funcionamiento eficiente y sin paradas.

Espectro de vibracion

Aparatos de ajuste: fundamental para el funcionamiento estable y productivo de las equipos.

En el ámbito de la ciencia contemporánea, donde la productividad y la estabilidad del sistema son de alta significancia, los aparatos de ajuste desempeñan un tarea crucial. Estos sistemas dedicados están creados para calibrar y asegurar elementos giratorias, ya sea en herramientas de fábrica, medios de transporte de traslado o incluso en equipos hogareños.

Para los expertos en reparación de dispositivos y los ingenieros, utilizar con sistemas de equilibrado es crucial para promover el operación uniforme y confiable de cualquier dispositivo giratorio. Gracias a estas herramientas innovadoras sofisticadas, es posible disminuir sustancialmente las oscilaciones, el sonido y la presión sobre los soportes, aumentando la vida útil de elementos importantes.

Igualmente trascendental es el papel que juegan los aparatos de equilibrado en la atención al comprador. El asistencia especializado y el soporte permanente utilizando estos equipos habilitan dar soluciones de gran estándar, incrementando la agrado de los usuarios.

Para los dueños de emprendimientos, la financiamiento en estaciones de equilibrado y detectores puede ser fundamental para optimizar la rendimiento y rendimiento de sus equipos. Esto es especialmente trascendental para los inversores que administran pequeñas y pequeñas negocios, donde cada elemento vale.

También, los dispositivos de calibración tienen una extensa implementación en el ámbito de la seguridad y el supervisión de nivel. Habilitan detectar eventuales errores, impidiendo mantenimientos costosas y problemas a los dispositivos. Más aún, los resultados obtenidos de estos aparatos pueden emplearse para maximizar procedimientos y incrementar la reconocimiento en plataformas de consulta.

Las sectores de implementación de los aparatos de calibración cubren múltiples sectores, desde la manufactura de vehículos de dos ruedas hasta el monitoreo de la naturaleza. No importa si se considera de enormes elaboraciones industriales o modestos establecimientos domésticos, los aparatos de balanceo son indispensables para promover un operación efectivo y sin interrupciones.