The Asia-Pacific Thermoplastic Elastomer Market was valued at 2,083 thousand tonnes in 2023 and is expected to grow significantly in the coming years. This growth is driven by the increasing demand for lightweight and high-performance materials in the automotive, construction, and electronics sectors across the region. Thermoplastic elastomers (TPEs) are gaining popularity due to their versatility, durability, and recyclability, making them ideal for applications in industries prioritizing sustainability and innovation. As manufacturers seek eco-friendly alternatives to traditional materials, the demand for TPEs continues to rise.

In this Asia-Pacific Thermoplastic Elastomer Market article, we’ll explore:

- What thermoplastic elastomers are and their applications.

- Key drivers of the market’s growth.

- Challenges and opportunities for innovation.

What Are Thermoplastic Elastomers (TPEs)?

Thermoplastic elastomers (TPEs) are a class of polymers that combine the properties of rubber and plastics. They offer elasticity, flexibility, and durability while being recyclable and lightweight. These materials are widely used in various industries due to their versatility and performance. Key applications include:

- Automotive: Used for lightweight components such as seals, gaskets, and interior parts to improve fuel efficiency and reduce emissions.

- Construction: Employed in roofing membranes, sealants, and insulation materials for enhanced durability and weather resistance.

- Electronics: Integrated into cables, connectors, and housings for flexibility and electrical insulation.

- Consumer Goods: Utilized in toys, footwear, and packaging due to their soft-touch properties and recyclability.

For instance, Asahi Kasei Corporation is advancing the development of new TPEs aimed at enhancing the recyclability of automotive parts. These innovative materials align with environmental goals and address the growing demand for sustainable components in vehicle manufacturing.

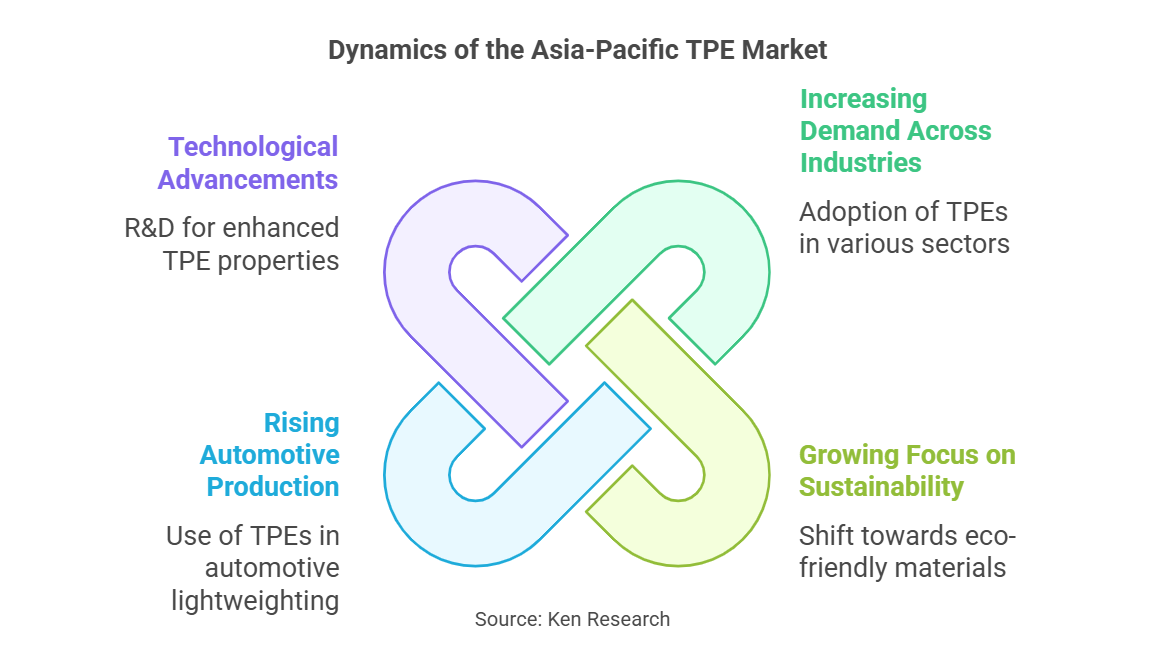

Key Drivers of the Asia-Pacific Thermoplastic Elastomer Market

Increasing Demand Across Industries

- Industries such as automotive, construction, and electronics are increasingly adopting TPEs to improve product performance and sustainability.

- Innovations in the India Thermoplastic Elastomer Market demonstrate how TPEs are being utilized in emerging markets to meet growing industrial demands.

Growing Focus on Sustainability

- Manufacturers are prioritizing recyclable and eco-friendly materials to meet environmental regulations and consumer preferences.

- TPEs are replacing traditional materials like PVC and rubber due to their lower environmental impact and recyclability.

Rising Automotive Production

- The automotive sector is a major consumer of TPEs, particularly in countries like China, Japan, and South Korea, where lightweight materials are critical for improving fuel efficiency and reducing emissions.

Technological Advancements

- Companies are investing in R&D to develop advanced TPE formulations with enhanced properties such as heat resistance, durability, and recyclability.

Regional Insights

China

China leads the Asia-Pacific Thermoplastic Elastomer Market, driven by:

- Rapid industrialization and a booming automotive sector.

- Increasing investments in electronics and consumer goods manufacturing.

- Government initiatives promoting sustainable materials and green manufacturing practices.

Japan

Japan is witnessing steady growth due to:

- Technological advancements in material science and manufacturing processes.

- A strong focus on reducing carbon emissions and promoting sustainable practices in industries like automotive and electronics.

South Korea

South Korea is another significant market, propelled by:

- High adoption rates of TPEs in automotive and electronics industries.

- Investments in research and development to create innovative and eco-friendly materials.

Key Players in the Asia-Pacific Thermoplastic Elastomer Market

The market is highly competitive, with key players leading the way in innovation and offering advanced solutions:

- LG Chem Ltd.: Known for its cutting-edge TPE solutions and focus on sustainability.

- Kraton Corporation: Specializes in developing high-performance TPEs for diverse industrial applications.

- Asahi Kasei Corporation: A leader in advancing recyclable TPEs for the automotive industry.

- Mitsubishi Chemical Corporation: Provides innovative TPE formulations tailored to meet regional demands.

- Tosoh Corporation: Focuses on enhancing the durability and performance of TPEs for construction and electronics applications.

These companies are continuously investing in R&D to meet the evolving demands of industries, supported by trends in the North America Thermoplastic Polyurethane Market.

Challenges in the Asia-Pacific Thermoplastic Elastomer Market

While the market is growing, it faces several challenges:

- High Costs of Advanced Materials: Premium TPEs can be expensive, limiting accessibility for small businesses and startups.

- Regulatory Hurdles: Ensuring compliance with environmental and safety regulations remains a challenge for some manufacturers.

- Competition from Alternative Materials: Traditional materials like rubber and PVC may pose a threat to TPEs in certain applications due to cost advantages.

Opportunities for Growth

The Asia-Pacific Thermoplastic Elastomer Market presents numerous growth opportunities:

- Expansion into Emerging Markets: Regions like Southeast Asia and India offer untapped potential due to increasing investments in automotive and electronics manufacturing.

- Focus on Recyclability and Sustainability: Developing eco-friendly TPEs can drive adoption in industries prioritizing sustainability and circular economies.

Conclusion

The Asia-Pacific Thermoplastic Elastomer Market was valued at 2,083 thousand tonnes in 2023 and is poised for significant growth, driven by the increasing demand for lightweight and high-performance materials, rising focus on sustainability, and technological advancements. As industries continue to prioritize innovation and eco-friendly solutions, this market will play a pivotal role in transforming manufacturing processes across sectors.

To stay ahead of the curve, businesses must address challenges like high costs and regulatory hurdles while exploring opportunities in recyclability and emerging markets.

For a deeper dive into this transformative market, download the sample report by Ken Research.