The energy industry is a diverse, complex industry that requires precision, efficiency and safety throughout the working life. A crucial instrument for achieving this requirement is computer-aided design, or CAD. This article looks at the advantages of computer-aided design (CAD) in the energy sector, where work -Highlights how it impacts productivity, system precision, safety and cost money saved. With numerous advantages above traditional drafting techniques, computer-aided design (CAD) technologies has fundamentally altered how engineers and designers work.

Enhancing Design Accuracy

Precision and Detail

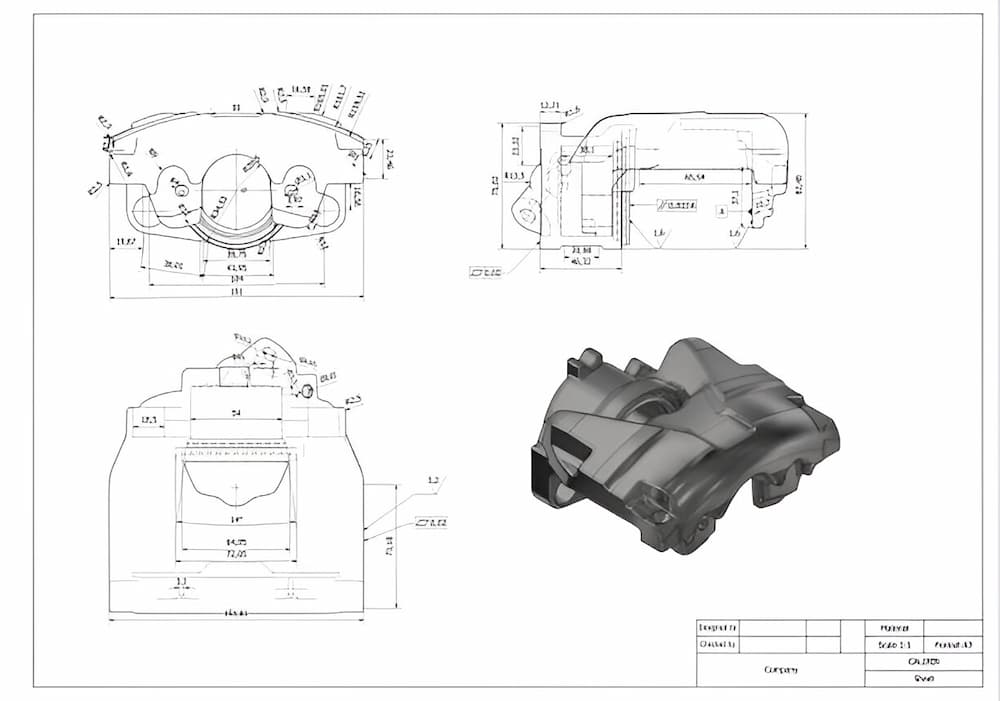

CAD Drafter models enable architects to create accurate and thorough designs. In the energy sector, where any small mistake can have catastrophic repercussions, accurate photography is essential. It would be challenging to make complex patterns and exquisite details by hand, but CAD software can help. By assuring that each part will fit perfectly, this accuracy reduces the possibility of error during installation and assembly.

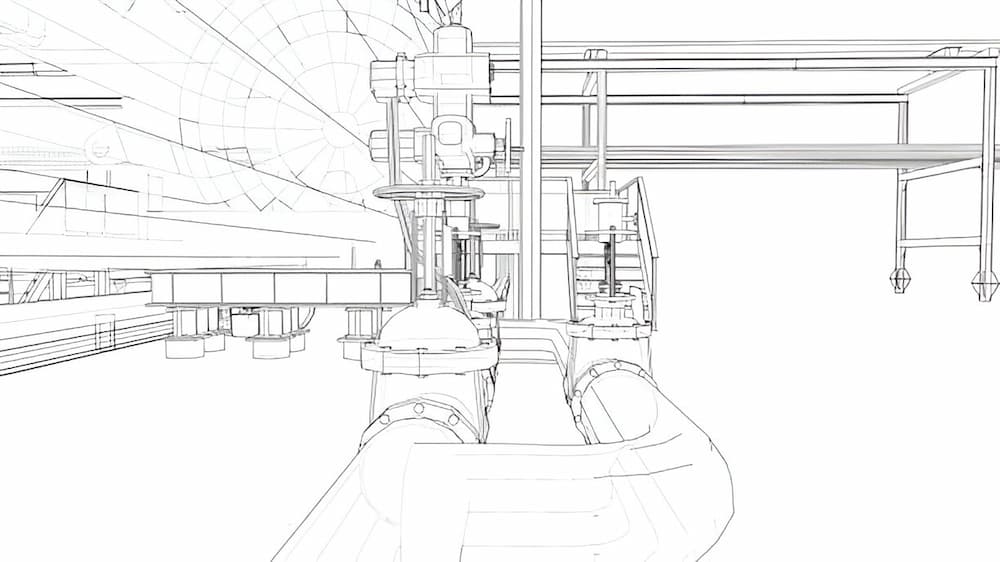

3D Modeling Capabilities

The ability to render CAD models in three dimensions is one of its key features. Three-dimensional models of pipelines, oil pipelines, and other structures can be made by engineers. This model offers a thorough grasp of the system and makes it easier to visualize and comprehend how the many components interact. Another advantage of 3D modeling is that it enables early problem discovery during the design phase, allowing for rapid adjustments and modifications.

Integration with Simulation Software

Simulation software can be connected with CAD drawings to test designs under different scenarios. Through this integration, engineers are able to monitor applications, identify any weaknesses, and improve the design to increase performance. especially in the oil and gas industry where the equipment lies in rough conditions.

Streamlining Project Management

Improved Collaboration

CAD drawings help project teams coordinate effectively. Engineers, designers, and other stakeholders may exchange information rapidly and make real-time updates when working on the same CAD file. This collaborative approach to ensuring consensus reduces the possibility of misunderstandings and inconsistencies.

Efficient Documentation

The documentation procedure is streamlined by BIM Outsourcing Services the use of CAD software. Every update and modification to the design is automatically documented, resulting in a thorough and current project record. Maintaining project schedules, allocating resources, and guaranteeing adherence to laws and industry standards all depend on this paperwork.

Enhanced Project Visualization

Project managers can produce intricate visual presentations of the project using CAD drawings. For the purpose of updating investors, stakeholders, and regulatory agencies on the project’s status, these visualizations are quite helpful. They facilitate decision-making and the acquisition of required permissions by giving a succinct and unambiguous picture of the project’s status.

Making Sure Everything Is Safe and Compliant

Precise Evaluation of Risk

In the oil and gas sector, safety is the first priority. Accurate risk evaluations are made easier by CAD drawings, which offer comprehensive representations of the infrastructure. To reduce risks, engineers can recognize possible hazards and create safety features. By taking a proactive stance, accidents can be avoided and worker and environmental safety can be guaranteed.

Compliance with Standards

There are stringent safety and environmental rules that apply to the oil and gas business. All designs are guaranteed to adhere to these criteria by means of CAD software and Civil Engineering Services. It provides tools for checking and validating designs against regulatory requirements, ensuring that the infrastructure meets all safety and environmental guidelines.

Training and Simulation

Training is another use for CAD designs. The intricate models can be used by technicians and engineers to conduct emergency response drills and simulate real-world circumstances. The staff needs this practical training to ensure they are knowledgeable about safety procedures and ready to manage any hazards.

Maximizing Economic Effectiveness

Reduced Material Wastage

The decrease in material waste is one of the main advantages of CAD drawing. Precise designs minimize waste by ensuring that materials are used effectively. Because of its efficiency, there is less of a demand for raw resources, which benefits the environment in addition to cutting expenses.

Time Savings

The use of CAD software greatly reduces the time required for design and drafting. The process is accelerated by automated features such as libraries of custom objects and templates. In the oil and gas industry, where deadlines are often limited and delays can result in significant financial losses, time savings are important.

Cost-effective Modifications

Any project will inevitably include adjustments and alterations. Modifications can be expensive and time-consuming when using standard drafting techniques. This procedure is made simpler by CAD software, which enables engineers to make changes fast and effectively. This allows for flexibility without significant additional cost.

Promoting sustainability and innovation

Encourage innovation

CAD technology encourages creativity by giving engineers the means to try out novel concepts and layouts. The capacity to build and evaluate virtual models promotes innovation and the generation of creative solutions.This innovation is important for the oil and gas industry, which requires technological advances to remain competitive.

Promoting environmental practices

Increased pressure in the oil and gas industry to adopt sustainable practices. This goal is supported by CAD drawings, which enable environmentally friendly and efficient design. Engineers can use computer-aided design (CAD) software to provide systems that maximize energy efficiency, reduce carbon emissions, and minimize environmental impact on.

Future-proofing Designs

As the field evolves, the need for flexible and forward-thinking systems grows. Design flexibility is made possible by CAD technology, which makes it easy to redesign and change to take into account new developments and evolving business needs This flexibility assures long-term project relevance and efficiency.

Conclusion

The oil and gas industry now relies heavily on CAD models for many of their benefits, including improved planning, easier project management, safety compliance, cost savings, and support for in sustainable development and innovation Industry leveraging the power of CAD technology Can improve efficiency, reduce risk and maintain its competitiveness in a complex and changing environment It is impossible to we will overstate the importance of CAD models in the oil and gas industry as they will have a significant impact on the direction of the project

FAQs

Why is computer design (CAD) significant to the oil and gas sector, and what does it entail?

The process of producing precise and detailed drawings using computerized design software is referred to as “CAD drawing”. The oil and gas business benefits from CAD design because it provides cost savings, enhances safety and compliance, streamlines project management, and improves planning accuracy.

In what ways do CAD models enhance safety within the oil and gas sector?

By providing accurate risk assessments, ensuring compliance with safety and environmental regulations, and enabling training and replication, computer-aided design (CAD) advances safety Computer-aided design ( CAD) in-depth modeling is useful for identifying potential problems in safety and security design.

What financial advantages may CAD drawings provide the oil and gas sector?

Waste reduction, time savings during design, and cost-effective modifications are some of the economic benefits of using CAD models. Accurate designs prevent material waste, automated features expedite drawing, and simple revisions lower change-related expenses.

How might CAD drawing help the oil and gas sector innovate and be more sustainable?

CAD drawing encourages creativity by giving users the tools to experiment with new ideas and concepts. It promotes sustainability by making it possible to build eco-friendly and efficient environments. Scalable, future proof designs that can accommodate new technologies and developed industry standards are another advantage of CAD technology.

Is it possible to use CAD models for training in the oil and gas industry?

It is possible to use CAD drawings for training, yes. Engineers and technicians can practice emergency response drills and replicate real-world scenarios with the help of detailed models. The staff needs this practical training to ensure they are knowledgeable about safety procedures and ready to manage any hazards.