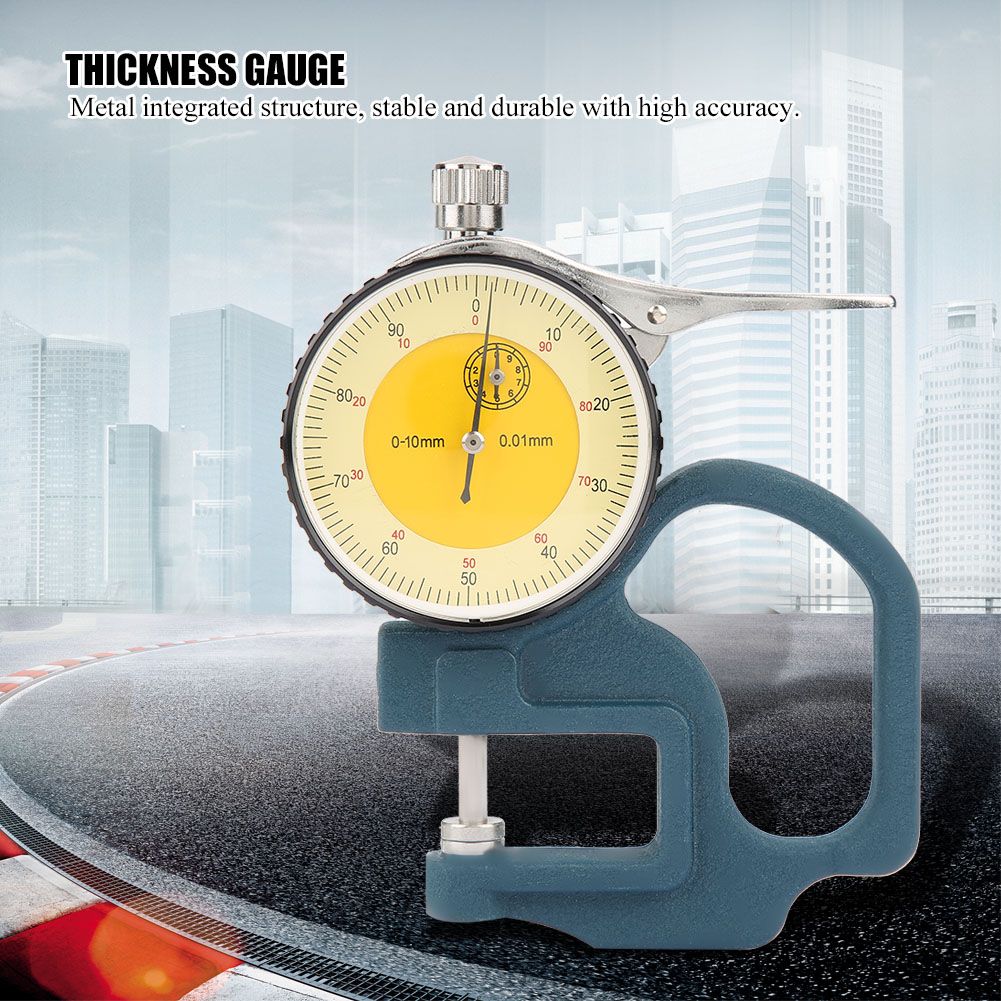

In industries where precision is crucial, ensuring the correct thickness of materials is a top priority. Whether it’s in manufacturing, automotive, aerospace, or construction, maintaining consistent quality standards is essential for producing reliable products. One of the most efficient tools for achieving this level of accuracy is the thickness gauge meter. This versatile device ensures that materials meet the required thickness specifications, contributing significantly to quality control processes. WJTIndia Pvt. Ltd, a leading name in measurement technology, provides advanced thickness gauge meters designed to enhance productivity and efficiency in quality assurance.

Understanding the Role of a Thickness Gauge Meter

A thickness gauge meter is a tool used to measure the thickness of materials such as metals, plastics, glass, and coatings. These meters use various technologies, including ultrasound, magnetic induction, and eddy currents, to provide precise measurements without damaging the material. By providing highly accurate thickness data, the gauge meter enables manufacturers to monitor material uniformity, ensuring consistent quality across production lines. This device is pivotal in detecting defects early, minimizing waste, and improving production efficiency.

Key Benefits of Using a Thickness Gauge Meter in Quality Control

1. Improved Precision in Measurements

One of the primary benefits of using a thickness gauge meter is the precise measurements it provides. Accurate thickness readings are essential for ensuring that products meet the required specifications. Variations in material thickness can lead to product defects or even failure, which could be costly for manufacturers. WJTIndia Pvt. Ltd’s thickness gauge meters are designed to provide exact readings, helping manufacturers maintain consistency and prevent defective products from reaching the market.

2. Non-Destructive Testing

Traditional methods of measuring material thickness often involve cutting or altering the material to check its dimensions, which can lead to waste. Thickness gauge meters, however, offer a non-destructive solution. These meters can measure the thickness of materials without damaging them, preserving the integrity of the product. Non-destructive testing is particularly important in industries such as aerospace and automotive, where the integrity of the material is critical to safety and performance.

3. Increased Production Speed

Efficiency is a key concern in any production process. With a thickness gauge meter, manufacturers can quickly and accurately measure materials, reducing the time spent on manual inspections. This increased speed allows production lines to move faster while maintaining high standards of quality control. WJTIndia Pvt. Ltd’s thickness gauge meters are designed for ease of use, enabling operators to take measurements quickly and efficiently, which ultimately boosts production rates.

4. Minimized Material Waste

Using a thickness gauge meter helps manufacturers reduce material waste. When material thickness is inconsistent, excess material may be used, leading to unnecessary waste and increased costs. By ensuring that materials meet the required thickness from the start, manufacturers can optimize their use of resources. This leads to more efficient production processes and reduced waste, resulting in cost savings. WJTIndia Pvt. Ltd’s thickness gauge meters help manufacturers minimize waste and improve overall production efficiency.

5. Enhanced Quality Control Documentation

In many industries, maintaining detailed records of quality control processes is a requirement for regulatory compliance. Thickness gauge meters can store measurement data, allowing manufacturers to document and analyze the thickness of materials over time. This data is essential for identifying trends, predicting potential issues, and ensuring compliance with industry standards. WJTIndia Pvt. Ltd’s meters are equipped with advanced data storage and reporting capabilities, making it easy for manufacturers to track and manage their quality control processes.

Applications of Thickness Gauge Meters in Various Industries

Thickness gauge meters are used across a wide range of industries. In the automotive industry, for example, these meters ensure that metal panels and parts meet the required thickness for durability and safety. In construction, thickness gauge meters are used to measure the thickness of structural materials, such as steel beams, to ensure they meet building codes. The aerospace industry relies on these meters to verify the thickness of materials used in aircraft components, where even the slightest deviation could compromise safety.

WJTIndia Pvt. Ltd offers thickness gauge meters suitable for a variety of applications. Their meters are built to handle the demands of different industries, providing accurate and reliable measurements that enhance both quality control and productivity.

Why Choose WJTIndia Pvt. Ltd for Thickness Gauge Meters?

WJTIndia Pvt. Ltd has established itself as a trusted name in the field of measurement technology. Their thickness gauge meters are known for their precision, durability, and ease of use. Designed to meet the needs of modern manufacturing processes, WJTIndia Pvt. Ltd’s meters provide accurate, non-destructive measurements that help businesses improve efficiency and maintain high standards of quality control. With a commitment to innovation and customer satisfaction, WJTIndia Pvt. Ltd is a reliable partner for companies looking to enhance their quality assurance processes.

Conclusion

In today’s competitive market, efficiency in quality control processes is essential for maintaining product consistency and reducing production costs. A thickness gauge meter is a critical tool that enables manufacturers to monitor and maintain material thickness with high accuracy. WJTIndia Pvt. Ltd’s range of thickness gauge meters offers the precision, speed, and reliability needed to improve efficiency in quality control processes across industries.