How EviView Is Transforming Manufacturing with Digital Intelligence

In a world where manufacturing must keep pace with rising demand, complex compliance requirements, and the need for real-time decision-making, operational excellence is no longer optional—it’s essential. EviView, an Ireland-based company founded in 2015, is tackling this challenge head-on with its unified daily management and operational intelligence platform.

Designed for medium to large manufacturers—particularly in the pharmaceutical, biotech, chemical, and energy sectors—EviView replaces outdated, paper-based systems with a streamlined, digital-first solution that boosts productivity, accountability, and performance.

Streamlining Operations with Unified Daily Management

At the heart of EviView’s offering is a shift away from fragmented and manual shop floor practices. Traditionally, shift handovers in manufacturing have been error-prone and inconsistent, relying on spreadsheets or physical logbooks. EviView digitizes this entire process.

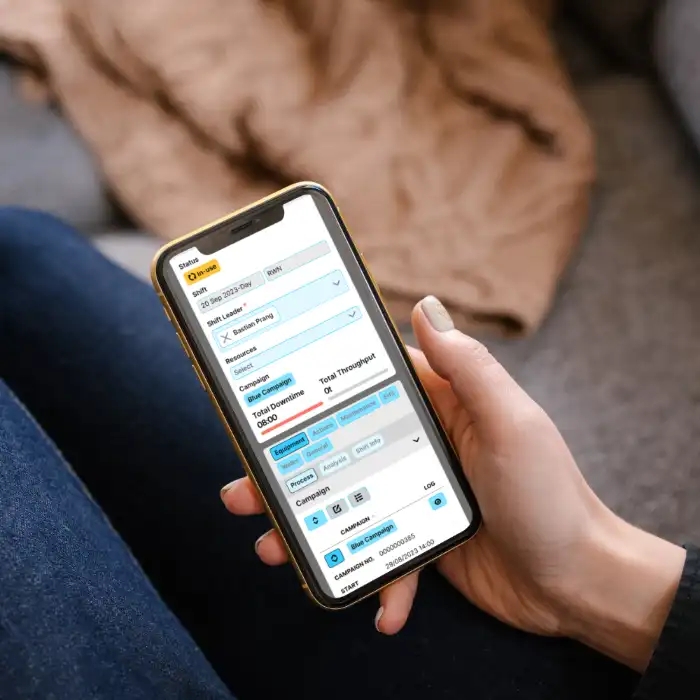

Using EviView, frontline teams and supervisors can access structured digital shift handovers, issue logs, and task tracking tools—all from a single mobile or desktop platform. The result? Improved information continuity between shifts, faster escalation of issues, and clearer communication from top to bottom.

Furthermore, tiered reporting and daily meetings are seamlessly integrated into the system, allowing site managers to access live performance dashboards and respond quickly to emerging trends or bottlenecks.

Real-Time Manufacturing Analytics & OEE Visibility

One of EviView’s standout features is its robust manufacturing analytics engine. This component gives companies the ability to track Overall Equipment Effectiveness (OEE), downtime, process variability, and team performance in real time. With interactive visualizations—like Pareto charts and fishbone diagrams—teams can conduct root-cause analyses and implement corrective actions based on real, actionable insights.

What sets EviView apart is its capacity to combine shift-level data with broader operational metrics. This creates a single source of truth that enhances visibility across departments and empowers data-driven decision-making.

A Platform for Continuous Improvement

EviView also serves as a launchpad for continuous improvement. The system allows users to capture improvement ideas directly from operators using digital A3 forms, which can then be tracked and implemented within structured workflows. Whether it’s reducing waste, improving safety, or optimizing batch processing, teams can monitor results in real time and scale solutions across the enterprise.

Additionally, EviView modernizes traditional Gemba walks by enabling managers to digitally capture notes, approve actions, and review findings—all on the go. This not only improves responsiveness but also ensures that critical observations are never lost in translation or buried in paperwork.

Compliance, Security, and Scalability

Given the heavily regulated environments in which many of its clients operate, EviView has invested heavily in compliance and data security. The platform provides complete audit trails, role-based permissions, and time-stamped logs to ensure traceability. EviView is built to meet ISO 27001 standards and supports both cloud-based and on-premise deployments in single-tenant virtual private cloud environments.

Its configurability makes it suitable for a range of site-specific processes. Whether you operate a standalone facility or a multi-site global network, EviView adapts to your workflows and integrates with systems like SAP and Palantir.

Measurable Results and Industry-Wide Impact

EviView’s impact is well-documented. For instance, Merck’s Arklow site reduced downtime by 30%, saving an estimated £66,000 annually, after deploying the platform. Safety reporting at several partner sites increased by over 300% thanks to more efficient issue tracking and resolution. One organization even reported €1.4 million in cost avoidance, along with freeing up 3.3 hours per day for every team using the platform.

Across pharmaceuticals, chemicals, food production, and energy, EviView continues to help manufacturers eliminate operational blind spots, improve team collaboration, and sustain high performance over time.

Conclusion

EviView is not just a digital tool—it’s a strategic enabler of transformation in modern manufacturing. By bringing together shift management, analytics, and improvement initiatives in one intuitive platform, it empowers teams to operate with clarity, speed, and consistency.

As digital transformation becomes a priority across industries, EviView offers a compelling solution that supports productivity, transparency, and compliance in even the most complex manufacturing environments.

For organizations still reliant on paper logs or scattered spreadsheets, now is the time to embrace the next generation of operational excellence and EviView is leading the charge.