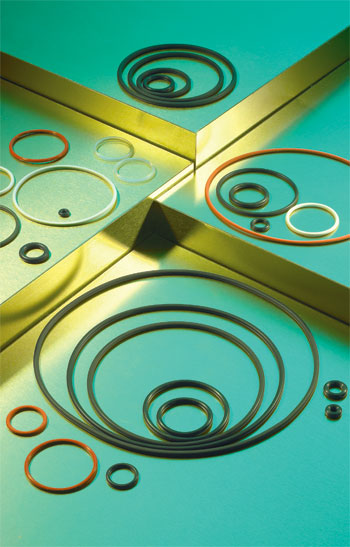

In the food and beverage industry, maintaining the highest sanitation standards is not just about compliance—it’s essential for ensuring product safety, quality, and consumer trust. Every piece of equipment used in processing, storage, and transportation must be designed to prevent contamination and allow for thorough cleaning. Silicone o-rings and rubber o-rings play a critical role in maintaining hygiene by creating airtight and watertight seals in tanks, pipelines, and processing equipment. These small but essential components help prevent leaks, bacterial growth, and cross-contamination, making them indispensable in food production facilities, breweries, and beverage processing plants.

The Importance of High-Quality Seals in Food Processing

The food and beverage industry relies on high-performance sealing solutions to ensure that every process remains sanitary. Whether in stainless steel storage solutions, beverage transfer systems, or brewing equipment, all seals must be resistant to high temperatures, cleaning chemicals, and exposure to food-grade ingredients. The right o-rings prevent unwanted leaks, help maintain pressure, and keep sensitive food and beverage products free from contamination.

Silicone o-rings are particularly popular in food processing environments because of their superior resistance to heat and chemicals. They are non-porous, meaning they don’t absorb moisture or allow bacteria to settle, making them an excellent choice for sterilisation-intensive applications. Their flexibility and durability ensure they maintain a secure seal even after repeated exposure to cleaning cycles and temperature fluctuations.

For industrial-grade applications requiring strong resistance to oils, fats, and acidic ingredients, rubber o-rings provide a durable and reliable solution. These o-rings are commonly found in insulated storage compartments, high-performance drawer systems, and beverage transfer systems, ensuring an airtight seal to maintain the freshness and quality of stored ingredients.

Specialised O-Rings for Beverage and Brewing Applications

In addition to silicone o-rings and rubber o-rings, different materials are used to meet the unique demands of the food and beverage industry. Viton o-rings are an excellent choice for high-temperature applications, particularly in brewing and food processing environments where resistance to heat, chemicals, and extreme conditions is essential. Their fluorocarbon composition makes them highly resistant to degradation, ensuring they maintain their sealing properties over long periods.

For food and beverage processing that involves contact with soft drinks or artificial sweeteners, CMPD o-rings offer a highly effective solution. CMPD No. 2197 material is specifically designed to handle soft drink applications and is particularly well suited for sealing systems that come into contact with ingredients like aspartame and NutraSweet®. These o-rings help maintain product integrity and prevent unwanted flavour contamination.

Meanwhile, Buna-N o-rings are widely used in beverage processing systems where oils and greases are present. Their excellent resistance to fuel, oils, and food-grade lubricants makes them ideal for applications in brewing equipment, high-pressure fluid transfer systems, and food processing machinery.

Ensuring Maximum Efficiency and Hygiene

Investing in high-quality o-rings, whether silicone o-rings, rubber o-rings, Viton o-rings, CMPD o-rings, or Buna-N o-rings, helps improve the efficiency of food and beverage processing facilities while maintaining the highest levels of hygiene. These sealing components ensure that equipment remains leak-free, contamination-resistant, and easy to clean, reducing downtime and preventing costly disruptions.

By choosing the right material for specific applications, businesses can extend the lifespan of their storage systems, maintain optimal product quality, and ensure compliance with food safety regulations. From breweries to large-scale food production plants, having the right o-rings in place is an essential step in maintaining a safe, efficient, and hygienic operation.