Electric motors are at the heart of industrial and commercial operations, driving essential machinery across multiple sectors. However, motors can experience electrical and mechanical stress without proper protection and controlled starting methods, leading to premature failure and increased maintenance costs. In this newsletter, we’ll explore the importance of motor protection and the role of soft starters in ensuring efficient and reliable motor operation.

Why Motor Protection Matters

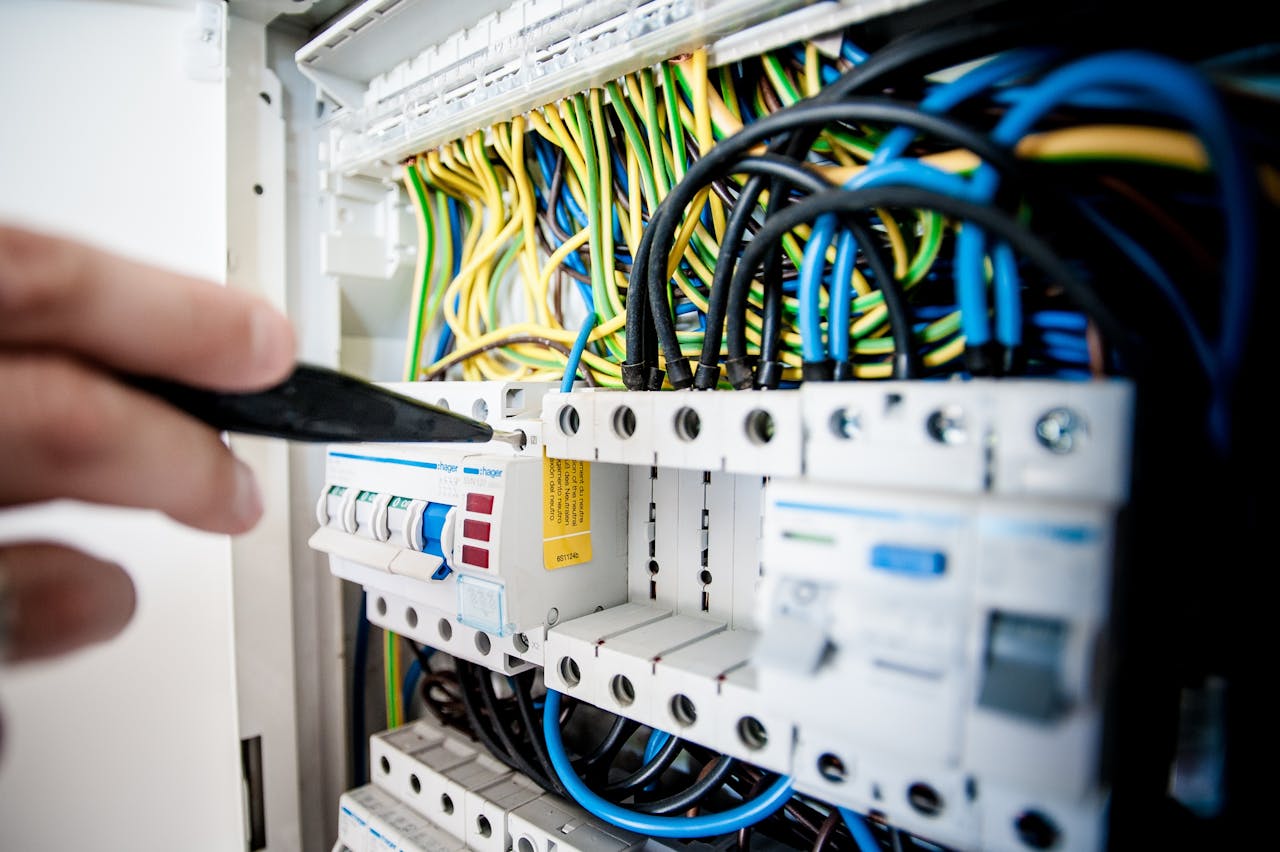

Motors operate in various environments, often under demanding conditions. Overcurrent, voltage fluctuations, overheating, and mechanical overload can damage motor components and disrupt operations. Proper motor protection not only extends equipment lifespan but also enhances safety, efficiency, and cost savings.

Key Motor Protection Methods:

- Overload Relays: Prevent excessive current that can overheat windings and damage insulation.

- Circuit Breakers & Fuses: Protect against short circuits and high fault currents.

- Thermal Protection: Monitors temperature rise in motor windings to prevent overheating.

- Phase Failure Protection: Detects and mitigates risks associated with phase imbalances or failures.

- Voltage & Frequency Monitoring: Ensures that motors operate within safe limits.

The Role of Soft Starters in Motor Protection

Traditional direct-on-line (DOL) starting methods apply full voltage to the motor instantly, resulting in high inrush current and mechanical stress. This sudden jolt can lead to electrical and mechanical failures over time. Soft starters mitigate these issues by gradually ramping up voltage and current, ensuring a smoother and controlled start.

Benefits of Using Soft Starters:

- Reduced Inrush Current: Limits high starting current, preventing voltage dips and reducing stress on electrical systems.

- Minimized Mechanical Wear: Soft acceleration reduces strain on gears, belts, and couplings, extending equipment life.

- Energy Efficiency: Reduces power surges and energy wastage, optimizing motor operation.

- Enhanced System Reliability: Protects against abrupt torque fluctuations that can lead to misalignment and breakdowns.

Star Delta Starter vs. Soft Starter

For applications where motor starting torque requirements are moderate, a Star Delta Starter is often used as a cost-effective method. It transitions the motor from a star connection (low voltage, reduced current) to a delta connection (full voltage) after a predetermined time delay, helping to reduce starting current. However, compared to modern soft starters, star delta starters offer less precise control and may not be suitable for all applications.

Soft starters, on the other hand, provide a more flexible and intelligent solution, offering programmable start and stop profiles, real-time monitoring, and smoother performance.

Choosing the Right Starting Method

Selecting between a star delta starter and a soft starter depends on several factors:

- Load Characteristics: High-inertia loads benefit more from soft starters.

- Operational Requirements: If smooth control and energy efficiency are priorities, a soft starter is ideal.

- Budget Constraints: Star delta starters are generally more affordable but may lack advanced control features.

- System Compatibility: Consideration of existing motor control systems and future scalability.

Final Thoughts

Investing in motor protection and the right starting method is crucial for ensuring long-term operational efficiency and equipment longevity. While traditional methods like star delta starters remain useful in many industries, soft starters offer a modern approach with improved control and protection.

Which motor starting method do you prefer for your applications? Share your thoughts in the comments!