One of product development’s most essential and exciting phases is transforming a prototype into a finished good. During this stage, concepts are realized broadly and turn into profitable ventures. But getting from a prototype to production requires meticulous preparation, close attention to detail, and a thorough comprehension of the design and manufacturing processes. This article’s exploration of the prototype-to-production process covers the steps, essential factors, typical problems, and methods for a smooth transition.

What Is the Prototype-to-Production Process?

The prototype-to-production process is a systematic method for expanding a product from an early model or prototype into full-scale manufacture. Prototypes are early working models created to evaluate various design, functionality, and performance elements. On the other hand, production facilities are set up for large-scale manufacturing, guaranteeing effectiveness, affordability, and quality requirements.

There are several stages to this process:

- Testing and Design Improvement

- Planning Production

- Developing Manufacturing Processes

- Final Adjustments and Quality Control

Every step is necessary to produce a finished good that satisfies consumer demands, complies with legal specifications, and can be made reliably and effectively.

Key Stages of the Prototype-to-Production Process

Design Refinement and Validation

- Goal: Improve the prototype to ensure it satisfies all quality, functional, and aesthetic requirements for large-scale manufacturing.

- Activities: Design refinement entails modifying the prototype in response to user input, performance evaluations, and market demands. Engineers and designers work together to fix any problems with the prototype and optimize the design for manufacturing.

- Validation: Ensuring the prototype complies with legal requirements and quality standards is critical. Numerous testing phases, including stress tests, environmental testing, and compliance testing (e.g., safety regulations), are frequently used to accomplish this.

Selection of Materials and Components

- Goal: Choose components and materials that can be produced on a big scale without sacrificing functionality or quality.

- Activities: Selecting the suitable materials requires balancing cost, durability, and quality. Other essential factors are production speed, environmental impact, and Availability.

- Supplier Sourcing: Keeping production consistent and quality requires partnerships with reputable components and materials vendors.

Development of Manufacturing Processes

- Goal: Create an effective, scalable production process that complies with quality and financial requirements.

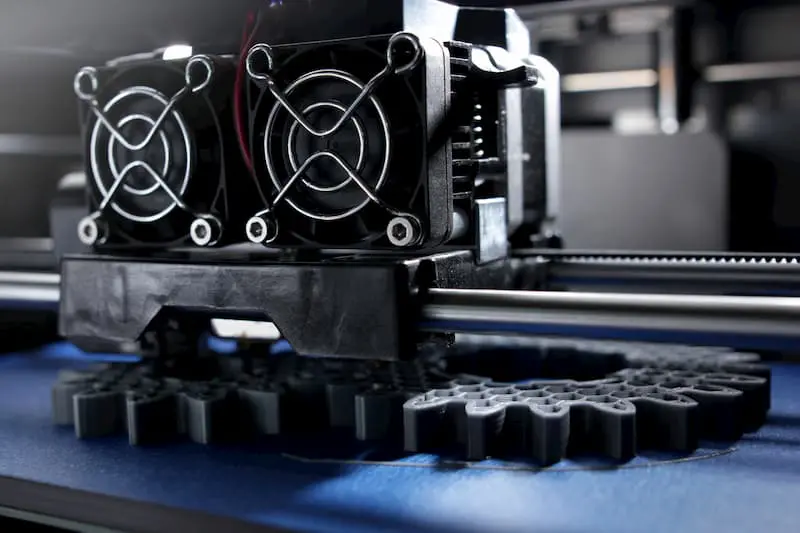

- Activities: Depending on the needs and design of the product, this includes choosing the best manufacturing techniques (such as CNC machining, additive manufacturing, and injection moulding).

- Tooling: Tooling is frequently required for products with custom components. Making fixtures, jigs, and moulds that expedite production and guarantee constant quality is part of this.

- Pilot Production: A pilot production run is frequently carried out to verify the manufacturing process. This phase facilitates modifications and aids in locating any possible production snags.

Final Adjustments and Quality Control

- Goal: Establish quality control procedures to guarantee that every unit satisfies the requirements.

- Activities: Quality control procedures include visual inspections, functional testing, and quality assurance systems like Six Sigma or Total Quality Management (TQM).

- Final Modifications: Following quality inspections, any last-minute changes are done before the product is put into full-scale manufacturing.

Scaling to Full Production

The product can go into total production when the pilot run has been assessed and improved. During this phase, the manufacturing workflow is streamlined, production output is tracked, and quality standards are upheld across all units.

Key Considerations for Prototype to Production

Design for Manufacturability (DFM)

- DFM guarantees that the product design can be produced at a reasonable scale and cost. This entails considering the constraints of manufacturing procedures, selecting quickly worked-with materials, and refining the design for effective production.

Expense Control

- The cost of moving from prototype to production is high, especially regarding setup, material selection, and tooling. A comprehensive cost study might aid in finding areas where costs can be reduced without compromising quality.

Management of the Supply Chain

- A steady supply chain for components and materials is essential for production to continue. This entails establishing trustworthy supplier connections and taking backup measures into account in case the supply chain is disrupted.

Protection of Intellectual Property (IP)

- Intellectual property must be protected during the production phase to stop rivals from stealing the design or manufacturing method. Trade secrets, patents, and trademarks should be protected to preserve the product’s distinctiveness and competitive position.

Compliance with Regulations and the Environment

- The manufacturers must guarantee the product’s compliance with applicable regulatory standards, including environmental criteria. This includes certifications that may be unique to the product type or target market, such as ISO, RoHS, and others.

Common Challenges in Moving from Prototype to Production

Quality Control

Maintaining consistent quality at scale can be difficult, mainly when dealing with complicated items. Quality control procedures must be implemented to prevent errors and preserve brand integrity.

Delays in Production

Tooling issues, supply chain interruptions, or unanticipated manufacturing difficulties can all cause delays. These delays might be lessened with project management and backup plans.

Overspending on Costs

Costs associated with moving from prototype to production can be unforeseen. Costs can be controlled by careful material selection, budgeting, and design modifications.

Scaling Complexity

Unexpected problems that didn’t appear during development, including supply chain problems or design faults that only become apparent in scale production, can be discovered during scaling. A pilot production phase can facilitate early detection and resolution of these problems.

Strategies for a Successful Prototype-to-Production Transition

Engage Stakeholders Early

Early in the process, involve all essential parties, including suppliers, engineers, and designers. Effective communication and teamwork guarantee that possible problems are resolved quickly and that everyone is on the same page regarding the production objectives.

Test and Iterate

It is essential to test at every stage of the procedure. Frequent testing guarantees that the final product satisfies all necessary criteria before total production and reduces the possibility of errors.

Make a Scaling Plan

Create a thorough plan for the product’s expansion, considering supply chain management and tooling. Make sure the manufacturing plant can meet rising demand.

Make a Quality Control Investment

To preserve product quality, use stringent quality control measures right away. Customer happiness depends on consistency, and production flaws can be avoided via quality management.

Make Efficiency Your Top Priority

For production to be cost-effective, efficiency is essential. Strategies such as automation, process enhancements, and material waste reduction must be considered to improve manufacturing efficiency and boost profitability.

FAQ’s

What are the main differences between a prototype and a production unit?

A prototype is an early iteration of a product intended to evaluate its viability, design, and functionality. Production units are finished goods created with cost, efficiency, and quality in mind and optimized for mass production.

What is the significance of the prototype-to-production process?

The procedure guarantees a dependable, scalable, and economical output. It helps businesses to meet client demands on a wider scale, improve their designs, and lower manufacturing costs.

What is Design for Manufacturability (DFM)?

DFM is a technique that maximizes product design for effective production. DFM can enhance quality, lower production costs, and expedite production schedules by simplifying and lowering the cost of producing the design.

What are some essential production-related quality control techniques?

Visual inspections, functional testing, and applying quality management systems such as Six Sigma and Total Quality Management are examples of quality control techniques. High standards are maintained in large-scale production thanks to these procedures.

Conclusion

The process from prototype to production is crucial for businesses hoping to introduce novel products to the market. Businesses may guarantee a successful transition with meticulous preparation, focus on quality, and efficient stakeholder communication. Businesses can quickly go from an original concept to a product ready for the market that fits customer needs and distinguishes them from the competition by adhering to established plans and proactively addressing any obstacles.