Introduction

Internal orders in SAP FICO play a crucial role in tracking, managing, and controlling costs associated with specific projects, tasks, or short-term activities within an organization. They serve as temporary cost objects, allowing businesses to monitor expenses separately from regular cost centers or profit centers. This capability is especially useful for one-time initiatives such as marketing campaigns, repairs, or special events. Internal orders help improve cost transparency, ensure accurate reporting, and facilitate cost allocation and settlement. By offering detailed tracking, they empower organizations to make informed financial decisions and maintain better control over project-related expenditures. One can check the SAP FICO Course Fees and join a training course for the best skill development.

What Is SAP FICO?

SAP FICO (Financial Accounting and Controlling) is a core module in SAP ERP systems, designed to help organizations manage and monitor financial transactions. It integrates financial data with business processes to provide a comprehensive overview of the company’s financial condition.

Financial Accounting (FI) focuses on external reporting, including balance sheets, profit & loss statements, and financial statements. It ensures compliance with accounting standards and regulatory requirements.

Controlling (CO), on the other hand, deals with internal reporting and helps in managing and optimizing costs and operations. It includes cost center accounting, internal orders, profitability analysis, and cost element accounting.

Together, SAP FICO enables organizations to track financial activities, generate reports for decision-making, and improve financial processes through automation. It is essential for both accounting and management teams to gain insights into the company’s financial performance.

Internal Orders in SAP FICO

In SAP FICO, Internal Orders are used to monitor costs and, in some cases, revenues within an organization. They act as temporary cost objects used for tracking specific tasks, projects, or events, allowing businesses to monitor the associated expenses separately from the main cost centers or profit centers. Internal orders are particularly useful for managing short-term or one-time activities like marketing campaigns, R&D projects, or maintenance work. Various tutorials on Sap Fico Introduction will help you learn more.

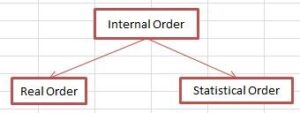

There are two main types of internal orders:

- Real Internal Orders: These are used for actual cost monitoring and can settle costs to other cost objects, such as cost centers, projects, or assets.

- Statistical Internal Orders: These are used for reporting purposes only and cannot settle costs. They are often used for analysing specific activities without affecting the company’s actual accounting.

Once the internal order is completed, the costs can be settled (allocated) to other cost objects like cost centers, profit centers, or projects. This process ensures that expenses are captured in the appropriate area of the business for financial reporting and analysis. Internal orders provide granular tracking and reporting for better cost management and budgeting. The SAP FICO Course Fees are nominal, and ensure the best learning opportunity for aspiring professionals.

Why Are Internal Orders in SAP FICO Relevant?

Internal orders in SAP FICO are highly relevant because they enable detailed tracking, monitoring, and controlling of costs associated with specific tasks, projects, or short-term initiatives within an organization. Their significance lies in providing a focused and structured way to manage costs that may not fit within the regular cost center structure, making them a vital tool for effective cost management and project accounting.

Key Reasons for Their Relevance:

- Detailed Cost Tracking: Internal orders allow businesses to track costs for specific activities such as events, repairs, or marketing campaigns. This ensures that every expense associated with a project is captured separately, giving a clear view of the total cost involved.

- Temporary Cost Assignment: Internal orders are ideal for temporary or one-time projects, helping organizations manage costs that don’t belong to long-term cost centers or profit centers. This temporary assignment of costs provides flexibility in financial management, making it easier to handle non-recurring or project-specific expenses.

- Better Cost Control and Reporting: By using internal orders, businesses can monitor and control project-related costs effectively. These orders also provide detailed reports on how resources are being utilized, enabling managers to make informed decisions regarding budgeting and resource allocation.

- Cost Allocation and Settlement: Once an internal order’s objective is fulfilled, the costs are settled (allocated) to other cost objects, such as cost centers, profit centers, or assets. This helps ensure that project expenses are accounted for correctly in the organization’s financial statements.

- Enhanced Transparency: Internal orders improve transparency in financial operations by offering a detailed breakdown of project-specific expenses. This transparency aids management in evaluating project performance and cost efficiency.

Thus, internal orders in SAP FICO offer businesses a powerful tool to manage costs for specific activities, leading to improved financial control, accurate reporting, and better decision-making. Refer to the Sap Fico Introduction to learn more about Internal Orders in SAP.

Conclusion

To summarise, Internal orders in SAP FICO are essential for tracking and managing project-specific or temporary costs within an organization. They provide detailed cost monitoring, better financial control, and transparency, ensuring that project expenses are accurately captured and reported. By enabling cost allocation and settlement to appropriate cost objects, internal orders help businesses maintain efficient financial management and support informed decision-making for project performance and budgeting.

equilibrado dinamico

Sistemas de balanceo: importante para el desempeno uniforme y efectivo de las dispositivos.

En el entorno de la avances contemporanea, donde la eficiencia y la estabilidad del equipo son de gran relevancia, los dispositivos de equilibrado juegan un papel esencial. Estos aparatos adaptados estan creados para balancear y asegurar elementos giratorias, ya sea en equipamiento industrial, transportes de movilidad o incluso en electrodomesticos caseros.

Para los especialistas en conservacion de dispositivos y los especialistas, trabajar con sistemas de calibracion es crucial para promover el operacion estable y fiable de cualquier mecanismo giratorio. Gracias a estas opciones innovadoras modernas, es posible minimizar notablemente las oscilaciones, el ruido y la carga sobre los sujeciones, aumentando la tiempo de servicio de piezas valiosos.

Asimismo significativo es el papel que juegan los equipos de calibracion en la asistencia al consumidor. El asistencia profesional y el soporte regular usando estos equipos posibilitan dar soluciones de alta estandar, mejorando la contento de los usuarios.

Para los titulares de negocios, la financiamiento en equipos de ajuste y dispositivos puede ser esencial para optimizar la eficiencia y rendimiento de sus sistemas. Esto es especialmente importante para los empresarios que gestionan reducidas y pequenas organizaciones, donde cada detalle importa.

Tambien, los dispositivos de calibracion tienen una amplia implementacion en el area de la proteccion y el monitoreo de nivel. Permiten encontrar potenciales problemas, impidiendo arreglos elevadas y averias a los equipos. Tambien, los indicadores extraidos de estos equipos pueden emplearse para mejorar sistemas y mejorar la visibilidad en plataformas de consulta.

Las campos de aplicacion de los aparatos de ajuste incluyen diversas ramas, desde la manufactura de bicicletas hasta el seguimiento de la naturaleza. No afecta si se considera de extensas manufacturas de fabrica o pequenos locales caseros, los sistemas de balanceo son esenciales para asegurar un operacion efectivo y sin paradas.

Comercializamos equipos de equilibrio!

Somos fabricantes, produciendo en tres naciones simultáneamente: Argentina, España y Portugal.

✨Contamos con maquinaria de excelente nivel y debido a que somos productores directos, nuestras tarifas son más bajas que las del mercado.

Disponemos de distribución global sin importar la ubicación, revise la información completa en nuestro sitio web.

El equipo de equilibrio es portátil, de bajo peso, lo que le permite equilibrar cualquier rotor en cualquier condición.

Vibración de motor

¡Vendemos dispositivos de equilibrado!

Producimos nosotros mismos, produciendo en tres países a la vez: Argentina, España y Portugal.

✨Nuestros equipos son de muy alta calidad y como no somos vendedores sino fabricantes, nuestro precio es inferior al de nuestros competidores.

Realizamos envíos a todo el mundo a cualquier país, lea la descripción de nuestros equipos de equilibrio en nuestro sitio web.

El equipo de equilibrio es móvil, de bajo peso, lo que le permite balancear cualquier eje rotativo en todas las circunstancias.

[b]Eliminate Vibration Issues and Improve Equipment Performance[/b]

Vibration is a silent killer of industrial machines. Imbalance leads to worn-out bearings, misalignment, and costly breakdowns. [b]Balanset-1A[/b] is the ultimate tool for detecting and correcting vibration problems in electric motors, pumps, and turbines.

[b]What Makes Balanset-1A Stand Out?[/b]

– Precise vibration measurement & balancing

– Compact, lightweight, and easy to use

– Two kit options:

[url=https://www.amazon.es/dp/B0DCT5CCKT]Full Kit on Amazon[/url] – Advanced sensors & accessories, Software for real-time data analysis, Hard carrying case

Price: [b]2250 EUR[/b]

[url=https://www.amazon.es/dp/B0DCT5CCKT][img]https://i.postimg.cc/SXSZy3PV/4.jpg[/img][/url]

[url=https://www.amazon.es/dp/B0DCT4P7JR]OEM Kit on Amazon[/url] – Includes core balancing components, Same high-quality device

Price: [b]1978 EUR[/b]

[url=https://www.amazon.es/dp/B0DCT4P7JR][img]https://i.postimg.cc/cvM9G0Fr/2.jpg[/img][/url]

Prevent unexpected breakdowns – Invest in [b]Balanset-1A[/b] today!

Balanset-1A: Innovative Compact Balancer & Vibration Analyzer

Industrial-grade Dynamic Balancing Solution

Balanset-1A stands as an groundbreaking solution for rotor balancing of rotors in their own bearings, created by Estonian company Vibromera OU. The device ensures professional equipment balancing at €1,751, which is significantly cheaper than traditional vibration analyzers while retaining exceptional measurement accuracy. The system enables field balancing directly at the equipment’s working position without necessitating removal, which is critically important for reducing production downtime.

About the Manufacturer

Vibromera OU is an Estonian company focusing in the creation and production of instruments for technical diagnostics of industrial equipment. The company is established in Estonia (registration number 14317077) and has offices in Portugal.

Contact Information:

Official website: https://vibromera.eu/shop/2/

Technical Specifications

Measuring Parameters

Balanset-1A provides precise measurements using a two-channel vibration analysis system. The device measures RMS vibration velocity in the range of 0-80 mm/s with an accuracy of ±(0.1 + 0.1?Vi) mm/s. The working frequency range is 5-550 Hz with potential extension to 1000 Hz. The system supports RPM measurement from 250 to 90,000 RPM with phase angle determination accuracy of ±1 degree.

Operating Principle

The device utilizes phase-sensitive vibration measurement technology with MEMS accelerometers ADXL335 and laser tachometry. Two mono-directional accelerometers measure mechanical vibrations proportional to acceleration, while a laser tachometer generates impulse signals for determining rotation frequency and phase angle. Digital signal processing includes FFT analysis for frequency analysis and specialized algorithms for automatic calculation of correction masses.

Full Kit Contents

The standard Balanset-1A delivery includes:

Measurement unit with USB interface – primary module with embedded preamplifiers, integrators, and ADC

2 vibration sensors (accelerometers) with 4m cables (optionally 10m)

Optical sensor (laser tachometer) with 50-500mm measuring distance

Magnetic stand for sensor mounting

Electronic scales for accurate measurement of corrective masses

Software for Windows 7-11 (32/64-bit)

Plastic transport case

Complete set of cables and documentation

Performance Capabilities

Vibrometer Mode

Balanset-1A works as a complete vibration analyzer with features for measuring overall vibration level, FFT spectrum analysis up to 1000 Hz, measuring amplitude and phase of the fundamental frequency (1x), and continuous data recording. The system provides visualization of time signals and spectral analysis for equipment condition diagnostics.

Balancing Mode

The device supports one-plane (static) and two-plane (dynamic) balancing with automatic calculation of corrective masses and their installation angles. The unique influence coefficient saving function allows significant acceleration of repeat balancing of identical equipment. A dedicated grinding wheel balancing mode uses the three-correction-weight method.

Software

The intuitive program interface provides step-by-step guidance through the balancing process, making the device usable to personnel without specialized training. Key functions include:

Automatic tolerance calculation per ISO 1940

Polar diagrams for imbalance visualization

Result archiving with report generation capability

Metric and imperial system support

Multilingual interface (English, German, French, Polish, Russian)

Application Areas and Equipment Types

Industrial Equipment

Balanset-1A is effectively applied for balancing fans (centrifugal, axial), pumps (hydraulic, centrifugal), turbines (steam, gas), centrifuges, compressors, and electric motors. In manufacturing facilities, the device is used for balancing grinding wheels, machine spindles, and drive shafts.

Agricultural Machinery

The device provides particular value for agriculture, where continuous operation during season is vital. Balanset-1A is used for balancing combine threshing drums, shredders, mulchers, mowers, and augers. The possibility to balance on-site without equipment disassembly enables eliminating costly downtime during peak harvest periods.

Specialized Equipment

The device is successfully used for balancing crushers of various types, turbochargers, drone propellers, and other high-speed equipment. The RPM frequency range from 250 to 90,000 RPM covers essentially all types of industrial equipment.

Superiority Over Competitors

Economic Value

At a price of €1,751, Balanset-1A delivers the functionality of devices costing €10,000-25,000. The investment breaks even after preventing just 2-3 bearing failures. Savings on third-party balancing specialist services amounts to thousands of euros annually.

Ease of Use

Unlike complicated vibration analyzers requiring months of training, mastering Balanset-1A takes 3-4 hours. The step-by-step guide in the software permits professional balancing by personnel without specific vibration diagnostics training.

Portability and Independence

The complete kit weighs only 4 kg, with power supplied through the laptop’s USB port. This enables balancing in remote conditions, at remote sites, and in inaccessible locations without separate power supply.

Universal Application

One device is adequate for balancing the broadest spectrum of equipment – from small electric motors to large industrial fans and turbines. Support for single and dual-plane balancing covers all typical tasks.

Real Application Results

Drone Propeller Balancing

A user achieved vibration reduction from 0.74 mm/s to 0.014 mm/s – a 50-fold improvement. This demonstrates the exceptional accuracy of the device even on small rotors.

Shopping Center Ventilation Systems

Engineers successfully balanced radial fans, achieving lower energy consumption, eliminated excessive noise, and extended equipment lifespan. Energy savings paid for the device cost within several months.

Agricultural Equipment

Farmers note that Balanset-1A has become an indispensable tool preventing costly breakdowns during peak season. Lower vibration of threshing drums led to reduced fuel consumption and bearing wear.

Cost and Delivery Terms

Current Prices

Complete Balanset-1A Kit: €1,751

OEM Kit (without case, stand, and scales): €1,561

Special Offer: €50 discount for newsletter subscribers

Wholesale Discounts: up to 15% for orders of 4+ units

Purchase Options

Official Website: vibromera.eu (recommended)

eBay: trusted sellers with 100% rating

Industrial Distributors: through B2B channels

Payment and Shipping Terms

Payment Methods: PayPal, credit cards, bank transfer

Shipping: 10-20 business days by international mail

Shipping Cost: from $10 (economy) to $95 (express)

Warranty: factory warranty

Technical Support: included in price

Summary

Balanset-1A represents an ideal solution for organizations striving to deploy an successful equipment balancing system without significant capital expenditure. The device opens up access to professional balancing, enabling small businesses and service centers to provide services at the level of large industrial companies.

The mix of reasonable price, ease of use, and professional features makes Balanset-1A an essential tool for modern technical maintenance. Investment in this device is an investment in equipment stability, decreased operating costs, and enhanced competitiveness of your business.

chicken road rtp

Chicken Road: Real Player Feedback

Chicken Road is a gamblinginspired arcade game that has drawn interest due to its straightforward mechanics, impressive RTP (98%), and innovative cashout option. We’ve collected honest feedback from actual players to see if it lives up to expectations.

What Users Appreciate

Many users praise Chicken Road for its fastpaced gameplay and ease of use. The option to withdraw winnings whenever you want introduces a tactical element, and the high RTP ensures it feels more equitable compared to classic slots. The demo mode is a hit with beginners, allowing players to test the game riskfree. Mobile optimization also gets high marks, as the game runs smoothly even on older devices.

Melissa R., AU: “A surprisingly entertaining and fair experience. The cashout function really enhances the gameplay.”

Nathan K., UK: “The retro arcade vibe feels invigorating. Plus, it works perfectly on my tablet.”

Gamers are also fond of the vibrant, retro aesthetic, making it both enjoyable and captivating.

Areas for Improvement

However, Chicken Road isn’t perfect, and there are a few issues worth noting. Certain players think the game is too predictable and doesn’t offer much variety. Others mention slow customer support and limited features. A common complaint is misleading advertising—many expected a pure arcade game, not a gambling app.

Tom B., US: “Initially enjoyable, but the repetition kicks in after a short while.”

Sam T., UK: “Advertised as a fun game, but it’s clearly a gambling app.”

Pros and Cons

Pros

Simple, fastpaced gameplay

With a 98% RTP, it offers a sense of equity

Free demo option for beginners to test the waters

Optimized for flawless mobile play

Cons

It might feel too predictable over time

Not enough features or modes to keep things fresh

Customer service can be sluggish and unreliable

Misleading marketing

Overall Assessment

Chicken Road stands out with its transparency, high RTP, and accessibility. Perfect for relaxed gaming sessions or newcomers to online betting. However, its reliance on luck and lack of depth may not appeal to everyone. To maximize enjoyment, stick to authorized, regulated sites.

Rating: 4/5

A balanced blend of fun and fairness, with potential for enhancement.