For small businesses, managing suppliers effectively can be a game-changer. Why? Because your suppliers play a significant role in ensuring you deliver quality products or services on time. If your supplier network isn’t optimized, it can lead to delays, increased costs, and dissatisfied customers. But when managed well, supplier relationships can contribute directly to growth, efficiency, and profitability.

Let’s dive into actionable strategies small businesses can implement to get the most out of their supplier management.

Understanding Supplier Management

- Definition and Key Components

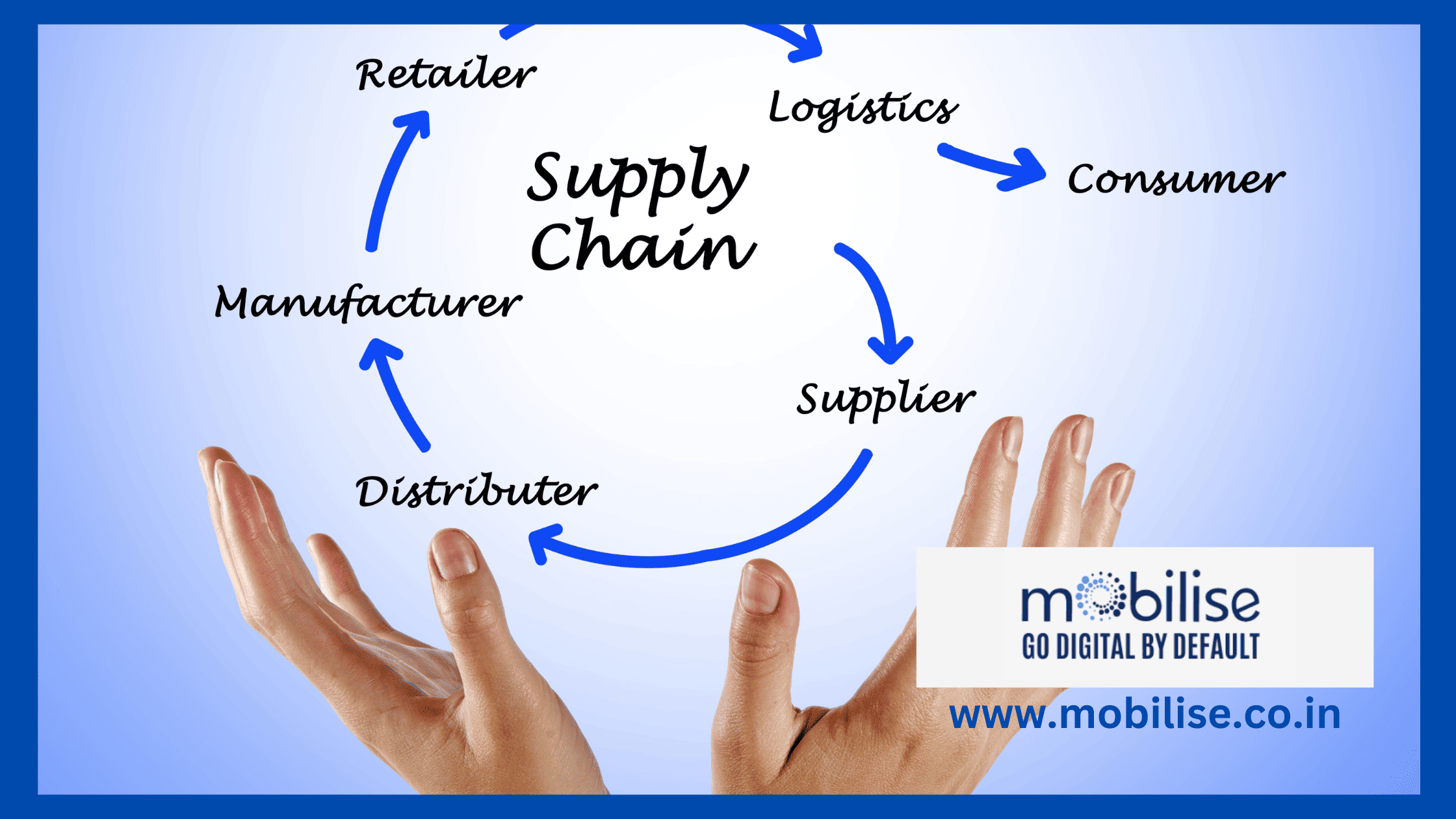

Supplier management refers to the process of strategically overseeing supplier relationships, procurement, and performance to maximize value for your business. It involves negotiation, communication, performance tracking, and ensuring the suppliers meet your business requirements.

Challenges Faced by Small Businesses in Supplier Management

Small businesses often grapple with limited resources, lack of negotiation leverage, and difficulties in vetting reliable suppliers. These challenges can hinder growth if not addressed strategically.

Building Strong Supplier Relationships

- The Importance of Trust and Communication

Trust and open communication lay the foundation for any successful partnership. Keep the lines of communication clear and ensure both parties are on the same page regarding expectations, deadlines, and quality standards.

- Strategies for Building Long-Term Partnerships

- Treat suppliers as partners rather than vendors.

- Offer feedback regularly to encourage mutual improvement.

- Commit to long-term contracts for reliability.

- Negotiation Tips for Small Businesses

- Negotiate smartly by researching market rates and demonstrating a willingness to collaborate on mutually beneficial terms.

Leveraging Technology for Supplier Management

ERP Systems and Their Role in Streamlining Processes

Enterprise Resource Planning (ERP) systems can centralize supplier information, streamline procurement processes, and improve decision-making through real-time data.

Benefits of Automation in Tracking and Communication

Automation reduces errors, saves time, and ensures you never miss critical deadlines or updates.

Implementing Effective Procurement Practices

Setting Clear Procurement Goals

Clearly define what you aim to achieve with procurement, whether it’s cost reduction, better quality, or faster deliveries.

The Role of Demand Forecasting

Forecasting ensures you order just the right amount—no more, no less. This reduces waste and prevents stockouts.

How to Manage Inventory Efficiently

- Use inventory management software to monitor stock levels.

- Establish reorder points to avoid overstocking or understocking.

- Diversifying Supplier Base

Why Relying on One Supplier Is Risky

Putting all your eggs in one basket can backfire. If your sole supplier faces disruptions, so will your business.

Tips for Finding and Vetting New Suppliers

- Attend trade shows and industry events.

- Check references and reviews thoroughly.

- Creating a Balanced Supplier Portfolio

- Diversify geographically and ensure you have backup suppliers for critical products.

Measuring Supplier Performance

Key Performance Indicators (KPIs) for Suppliers

Monitor metrics like on-time delivery rate, defect rate, and cost efficiency to assess supplier reliability.

Regular Performance Reviews

Schedule quarterly reviews to discuss performance metrics and address any concerns.

Addressing Underperformance Effectively

Communicate issues constructively and work together on corrective action plans.

Sustainable Supplier Management Practices

Why Sustainability Matters in Supplier Management

Sustainability not only boosts your brand reputation but also ensures long-term supplier reliability.

Collaborating with Suppliers on Sustainable Practices

Partner with suppliers to adopt eco-friendly materials, reduce waste, and implement ethical labor practices.

Cost Management in Supplier Relations

Identifying Areas to Reduce Costs

Review contracts regularly and consolidate purchases to negotiate better pricing.

The Impact of Bulk Purchasing and Discounts

Ordering in bulk or bundling purchases can lead to significant savings over time.

Conclusion

Optimizing supplier management isn’t just about cutting costs—it’s about building relationships, leveraging technology, and ensuring sustainability. With the right strategies, even small businesses can manage their suppliers like a pro, driving growth and efficiency.

FAQs on Supply Chain Management Solution

Q1. What is supplier management, and why is it important for small businesses?

Ans. Supplier management is overseeing supplier relationships and performance to ensure value. It helps small businesses minimize costs and improve reliability.

Q2. How can small businesses improve communication with suppliers?

Ans. Regular meetings, clear expectations, and timely feedback are key to improving communication.

Q3. What tools are most effective for supplier management?

Ans. Tools like SAP Ariba and inventory management software are excellent for streamlining processes.

Q4. How can small businesses ensure supplier reliability?

Ans. Vet suppliers thoroughly, monitor performance, and diversify your supplier base for added security.

Q5. What are the risks of not diversifying a supplier base?

Ans. Dependence on a single supplier can lead to operational disruptions if they fail to deliver.