1. Strength and Durability: Structural steel is known for its high strength-to-weight ratio, which means it can withstand heavy loads while remaining relatively lightweight. It’s also highly durable and can resist corrosion, weathering, and other environmental factors better than many other construction materials.

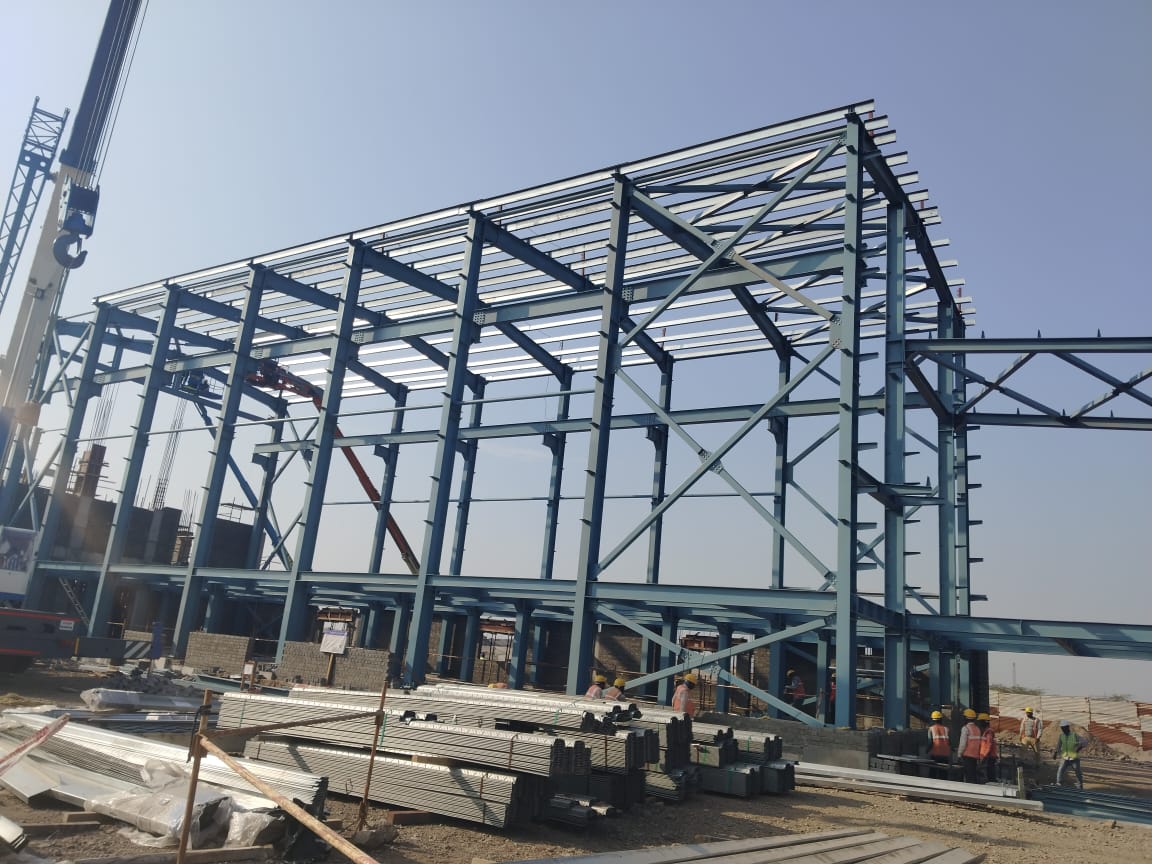

2. Design Flexibility: Steel can be easily molded and fabricated into various shapes, allowing architects and designers greater flexibility in creating innovative and complex structures. This flexibility enables the construction of large, open spaces without the need for intermediate columns or walls.

3. Speed of Construction: Steel structures can be prefabricated off-site, allowing for faster construction times compared to traditional building methods. This can result in cost savings and reduced labor requirements.

4. Cost-Effectiveness: Although the initial cost of steel may be higher than some other materials, its long-term durability and low maintenance requirements often make it a cost-effective choice over the life cycle of a building. Additionally, the speed of construction can lead to savings in labor and financing costs.

5. Sustainability: Steel is a highly sustainable material. It is recyclable and can be reused or repurposed at the end of its life. Additionally, the energy required to produce steel has decreased significantly over the years, making it an environmentally friendly choice.

6. Fire Resistance: Contrary to popular belief, steel is inherently fire-resistant. It doesn’t burn, and its strength is not compromised by heat like other materials such as wood. This makes it a safer choice for building construction, especially in areas prone to wildfires or with strict fire safety regulations.

7. Adaptability and Expansion: Steel structures can easily be modified or expanded upon in the future, allowing for changes to the building’s layout or function without significant structural alterations.

Disadvantages:

1. Initial Cost: The initial cost of using structural steel can be higher compared to other construction materials such as wood or concrete. This can be a barrier for some projects, particularly those with tight budgets.

2. Specialized Labor and Equipment: Working with structural steel requires specialized labor and equipment, which may increase construction costs. Welding, cutting, and erecting steel structures require skilled workers and specialized machinery.

3. Fire Protection: Although steel is inherently fire-resistant, it can lose strength and integrity when exposed to high temperatures for prolonged periods. Therefore, fire protection measures such as fireproofing coatings or insulation may be necessary to ensure the safety of occupants.

4. Corrosion Protection: While steel is resistant to corrosion, it can still corrode over time, especially in harsh environments such as coastal areas. Proper corrosion protection measures, such as coatings or galvanization, need to be implemented to prolong the life of the structure.

5. Design Complexity: While steel offers design flexibility, complex designs may require extensive engineering and detailing, which can increase design and construction costs. Additionally, changes to the design during construction can be more challenging and costly compared to traditional building materials.

Overall, while structural steel offers numerous advantages such as strength, durability, design flexibility, speed of construction, and sustainability, it also comes with some disadvantages such as initial cost, specialized labor and equipment requirements, fire protection needs, corrosion protection requirements, and potential design complexity. These factors should be carefully considered when choosing structural steel for building construction.